The Ultimate Guide to 3D Composite Drainage Net: Why It’s the Future of Civil Engineering

Release time:

2026-01-27

Discover the benefits and applications of 3D Composite Drainage Net. Learn how this tri-planar geocomposite improves landfill and roadbed drainage. Get a quote from a leading manufacturer.

In the world of modern civil engineering and environmental protection, managing water flow is the difference between a project’s long-term success and a costly failure. Traditional drainage methods like gravel layers are increasingly being replaced by more efficient, cost-effective, and durable solutions. Leading this charge is the 3D Composite Drainage Net.

1.What is a 3D Composite Drainage Net?

A 3D Composite Drainage Net (also known as a drainage geocomposite) is a high-tech geosynthetic material. It consists of a unique tri-planar geonet core thermally bonded with a non-woven needle-punched geotextile on either one or both sides.

The core structure provides a high-capacity flow path for liquids and gases, while the geotextile layers act as filters to prevent soil particles from clogging the drainage core.

2.Key Benefits of Using 3D Geocomposites

Why are international contractors shifting away from traditional aggregates? Here’s why:

High Hydraulic Conductivity: The tri-planar structure can maintain high flow rates even under significant compressive loads.

Superior Durability: Made from high-density polyethylene (HDPE), it resists chemical corrosion, UV radiation, and biological degradation.

Cost-Effective Logistics: One roll of 3D drainage net replaces several truckloads of gravel. This drastically reduces transportation costs and carbon footprint.

Easy Installation: It is lightweight and flexible, allowing for quick deployment regardless of the terrain or weather conditions.

3.Common Applications in Global Infrastructure

The versatility of the 3D Composite Drainage Net makes it a staple in various sectors:

1. Landfill Systems

It is used in landfill liner systems for primary and secondary leachate collection. It efficiently directs hazardous fluids to collection points, preventing groundwater contamination.

2. Roadbed and Railway Drainage

By quickly draining excess water from the base and sub-base layers, it prevents frost heave and structural weakening, significantly extending the lifespan of highways and tracks.

3. Tunnel and Retaining Wall Drainage

In underground construction, water pressure can be devastating. 3D geocomposites relieve hydrostatic pressure by providing a continuous drainage path behind tunnel linings and retaining walls.

4.Technical Specifications at a Glance

| Feature | Description |

|---|---|

| Material | High-Density Polyethylene (HDPE) + PET/PP Geotextile |

| Thickness | Typically 5mm to 8mm |

| Tensile Strength | High MD and CMD strength for structural integrity |

| Flow Capacity | High-pressure drainage performance |

5.How to Choose the Right Supplier?

When sourcing 3D Composite Drainage Nets for your project, look for manufacturers that provide:

ISO and CE Certification: Ensuring the material meets international safety and quality standards.

Customization Options: Ability to adjust the thickness and geotextile weight based on specific site requirements.

Technical Support: A partner who understands the engineering behind the product, not just a salesperson.

6.Conclusion

The 3D Composite Drainage Net is no longer an "alternative" material—it is a standard for sustainable and efficient engineering. Whether you are working on a municipal landfill or a high-speed railway, this geocomposite ensures your project stays on solid (and dry) ground.

Are you planning your next infrastructure project?

Contact our technical team today for a free sample or a customized quote tailored to your specific drainage requirements.

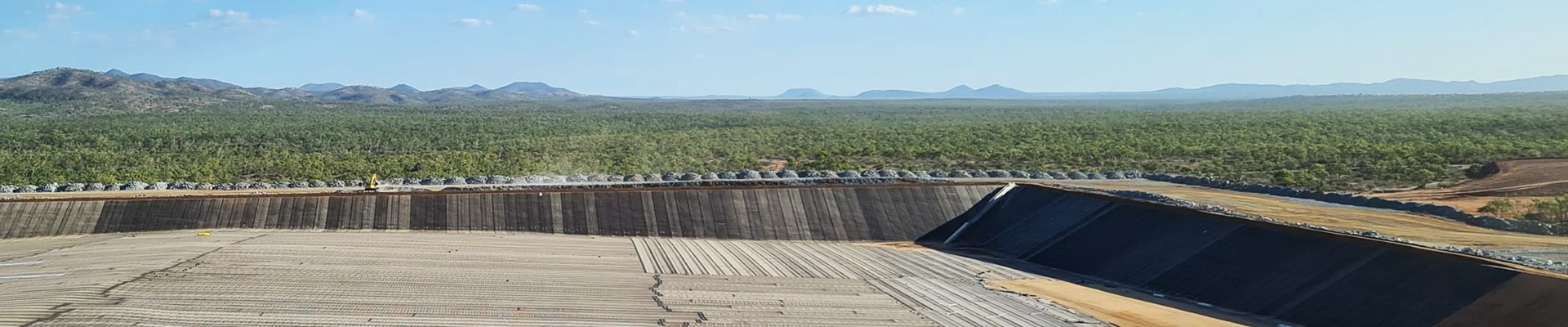

PROJECT CASES