Standard Certified By

ASTM Standard Geosynthetic Clay Liners | High-Performance Hydraulic Barriers

Classification :

PRODUCT DETAILS

1. Certified Excellence in Hydraulic Containment

Longxiang New Materials is dedicated to manufacturing Geosynthetic Clay Liners (GCLs) that not only meet but often exceed global regulatory requirements. Our GCL products are certified to rigorous ASTM International Standards and serve as reliable, high-performance hydraulic barriers for the most critical environmental and civil engineering projects.

We use laboratory-verified natural Sodium Bentonite clay, encapsulated in high-tenacity geotextiles, creating an engineered composite that delivers ultra-low permeability and proven long-term sealing integrity. Choose our ASTM Standard GCLs for guaranteed compliance and peace of mind on your high-stakes containment needs.

2. Adherence to Global Standards

Quality assurance is the foundation of our manufacturing process. Every batch of GCL undergoes strict, independent testing to ensure performance meets or surpasses the following key standards:

ASTM D5887 (Hydraulic Conductivity): Verifies the ultra-low permeability necessary for effective containment.

ASTM D5993 (Mass per Unit Area): Guarantees the consistent and required loading of sodium bentonite clay within the product.

ASTM D6496 (Peel Strength): Ensures the mechanical bond of our reinforced GCL remains intact during installation and service life.

GRI-GCL3 Specification: Compliance with the Geosynthetic Research Institute's widely recognized minimum specification requirements for GCLs.

3. High-Performance Benefits for Engineers

Proven Low Permeability: Our GCL consistently achieves a hydraulic conductivity of $\le 5 \times 10^{-11} m/s$, which is often orders of magnitude better than typical compacted clay liners.

Engineered Self-Sealing: The high-swell sodium bentonite clay immediately self-seals minor punctures or tears that might occur, maintaining the integrity of the hydraulic barrier.

Superior Durability: The GCL structure resists damage from differential settlement and freeze-thaw cycles better than rigid barriers.

Certified Shear Strength: For reinforced variants, the mechanical bonding is quantified and certified to handle high shear loads, crucial for slope and embankment stabilization.

4. Critical Applications Requiring Certification

Projects demanding guaranteed performance rely on our ASTM Standard GCLs:

Hazardous Waste Containment: Ensuring zero leakage for toxic industrial residues.

Regulated Landfill Base Liners: Meeting strict government requirements for barrier systems in Municipal Solid Waste (MSW) landfills.

Water Reservoirs & Dams: Providing certified, long-term anti-seepage solutions for potable water infrastructure.

Environmental Remediation: Used in brownfield sites and environmental cleanup operations where verified performance is mandatory.

5. Technical Documentation and Data

We provide comprehensive technical transparency.

| Performance Test | ASTM Standard | Required Data | Document Availability |

|---|---|---|---|

| Hydraulic Conductivity | D5887 | $\le 5 \times 10^{-11} m/s$ | TDS & QC Report |

| Bentonite Mass | D5993 | Verified kg/m² | QC Report |

| Shear Strength | D6243 | Tested kPa | TDS & Lab Report |

6. Partnering for Compliance

When your project success hinges on passing inspection, trust Longxiang New Materials. We understand the regulatory landscape and provide the necessary documentation to satisfy engineers, consultants, and project auditors worldwide. We are not just a supplier; we are your partner in certified containment solutions.

7. Call to Action

Secure your project with GCLs certified to the highest standards. Contact our technical sales team for samples, custom specifications, and compliance documentation.

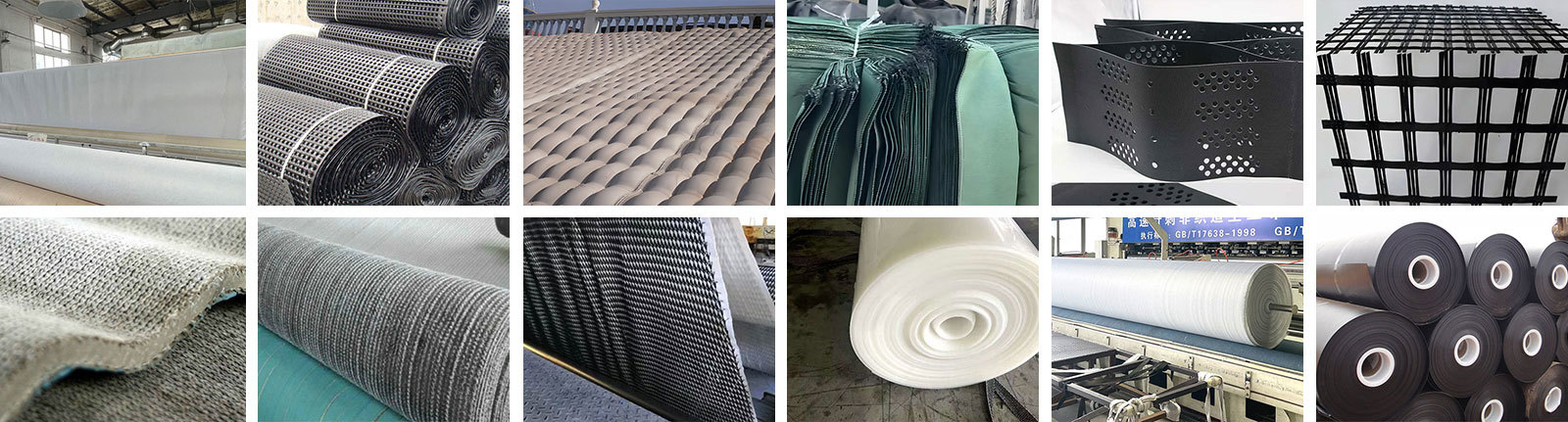

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE