Standard Certified By

GCL - Bentonite Clay Liner with Geomembrane Composite | Longxiang New Materials

Classification :

PRODUCT DETAILS

1. The Ultimate Double-Barrier System

Longxiang New Materials presents the next generation of containment technology: the Geosynthetic Clay Liner (GCL) with Geomembrane Composite. This advanced product combines the self-sealing properties of sodium bentonite clay with the absolute impermeability of a flexible geomembrane film (HDPE/LLDPE).

By laminating a geomembrane to the surface of a standard needle-punched GCL, we create a "Composite GCL" that offers a dual-layer defense system. It is the ideal solution for projects requiring the highest level of leak protection and gas containment.

2. Why Choose a GCL with Geomembrane Composite?

While standard GCLs are excellent, our Geomembrane Composite GCL takes performance to a new level:

100% Waterproofing (Even before Hydration): The attached geomembrane film provides an immediate hydraulic barrier, while the bentonite layer acts as a backup self-sealing reserve.

Superior Gas Barrier: Unlike standard porous textiles, the geomembrane film effectively blocks the migration of hazardous gases (such as Radon and Methane) and odors, making it perfect for landfill capping.

Protection Against Desiccation: The film prevents the bentonite clay from drying out (desiccation) due to heat or root absorption, ensuring the clay remains hydrated and effective.

Chemical Resistance: The added plastic layer offers enhanced resistance to aggressive chemicals that might otherwise affect the geotextiles.

3. Technical Structure & Specification

Our composite GCL is manufactured by bonding a flexible Geomembrane (typically 0.2mm - 0.5mm HDPE/LLDPE) to the non-woven geotextile side of the GCL.

Layer 1: High-quality PE Geomembrane Film (Barrier Layer).

Layer 2: Non-woven Geotextile (Protection & Reinforcement).

Layer 3: Natural Sodium Bentonite (Active Sealing Core).

Layer 4: Woven Geotextile (Base Carrier).

| Feature | Standard GCL | Longxiang Composite GCL |

|---|---|---|

| Hydraulic Conductivity | $5 \times 10^{-11}$ m/s | $< 1 \times 10^{-13}$ m/s (Virtually Impermeable) |

| Gas Permeability | Moderate | Extremely Low |

| Root Resistance | Moderate | High |

| Installation | Overlap with Paste | Overlap with Welding or Tape |

4. Critical Applications

This product is specifically engineered for high-risk and sensitive environments:

Landfill Caps & Closures: Prevents rainwater infiltration and stops landfill gas (methane) from escaping into the atmosphere.

Basement & Tunnel Waterproofing: Provides absolute water-tightness for underground structures where repair is impossible.

Roof Gardens (Green Roofs): Protects the building structure from water and aggressive plant roots.

Secondary Containment: For fuel storage tanks where zero leakage is mandated.

5. Why Partner with Longxiang New Materials?

As a specialized manufacturer, Longxiang New Materials utilizes state-of-the-art lamination technology to ensure a high bond strength between the geomembrane and the GCL.

Factory-Direct Pricing: Get the best value for this premium composite product.

Customization: We can adjust the thickness of the geomembrane film (0.2mm to 1.0mm) and the mass of the bentonite to suit your engineering design.

Quality Control: Rigorous testing for peel strength and permeability ensures the composite layers will not delaminate during installation.

6. FAQ: Composite GCL

- Q: How do you join/seam the Composite GCL?

- A: Unlike standard GCLs that just use bentonite paste, Composite GCLs often require the geomembrane overlap to be heat-welded or taped, while the GCL layer is supplemented with bentonite powder. We provide a full installation guide upon request.

- Q: What is the lifespan of the Geomembrane Composite?

- A: The combination of durable HDPE/LLDPE and natural bentonite ensures a service life of decades, even in harsh environmental conditions.

7. Get a Quote for Composite GCL

Upgrade your containment strategy with Longxiang New Materials. Contact us today for free samples, technical data sheets (TDS), and a competitive price quote for our Bentonite Clay Liner with Geomembrane Composite.

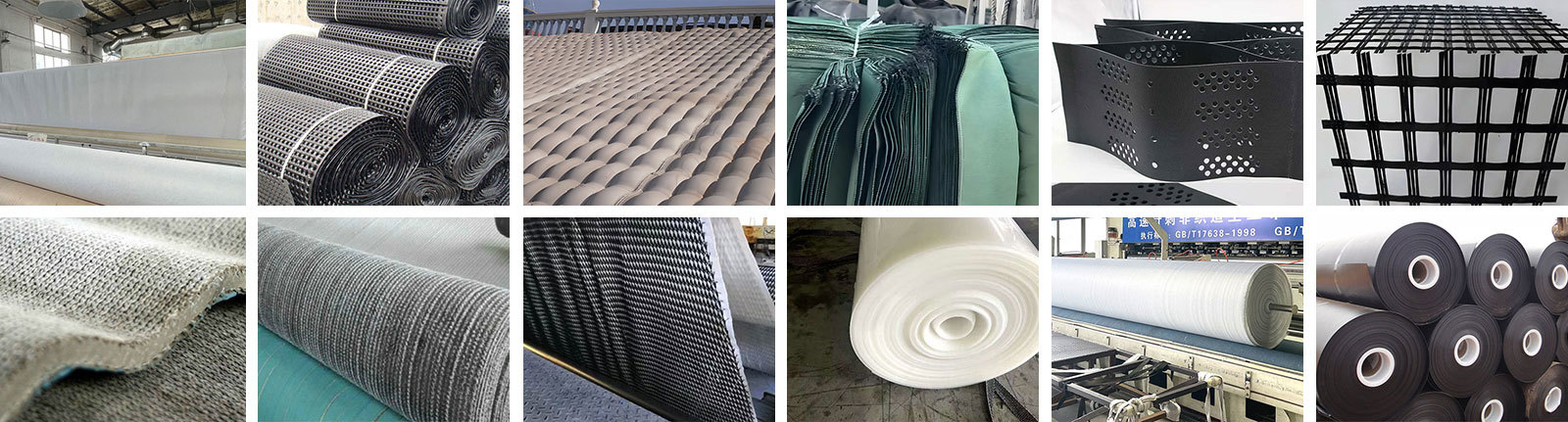

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE