Standard Certified By

Extra Wide Nonwoven Geotextile Roll up to 8m for Large Scale Projects

Classification :

PRODUCT DETAILS

Maximize Efficiency with Super-Wide Width Geosynthetics

Our Extra Wide Nonwoven Geotextile sets a new standard for efficiency in large-scale civil engineering. While standard market widths are typically limited to 4m or 6m, we utilize advanced production lines to manufacture Geotextile Rolls up to 8 meters (26.2 feet) in width.

Designed specifically for mega-projects such as landfills, airports, tailings dams, and land reclamation, these extra-wide rolls significantly reduce the number of overlaps required. This translates directly to reduced material waste, faster installation speeds, and fewer weak points in the geosynthetic system, ensuring superior integrity for your infrastructure.

Why Choose 8m Wide Rolls? (Core Advantages)

-

Huge Material Savings (Minimize Overlaps):

Standard installation requires a 15cm–30cm overlap between rolls. On a massive site (e.g., 100,000 m²), using 8m rolls instead of 4m rolls cuts the number of overlaps by 50%, saving thousands of square meters of wasted "overlap material."

-

Accelerated Installation Schedule:

Fewer rolls to deploy and fewer seams to sew or weld means your crew can cover larger areas in less time. This is critical for projects with tight deadlines or short weather windows.

-

Enhanced System Integrity:

Seams are often the weakest point in any geosynthetic layer. By reducing the number of seams, we minimize the risk of leakage, soil infiltration, or mechanical failure, providing a safer solution for Landfill Liners and Tailings Dams.

-

Customizable Lengths:

We can customize the roll length to match your specific site dimensions, further reducing cutting waste at the end of the roll.

Technical Specifications

We offer this extra-wide format in various weights to suit separation, filtration, or protection needs.

| Property | Test Method | Unit | Specification Range |

| Roll Width | - | m | 4m – 8m (Customizable) |

| Material | - | - | High Tenacity PP / PET Staple Fiber |

| Mass Per Unit Area | ASTM D5261 | g/m² | 100 – 1200 (Light to Heavy Duty) |

| Grab Tensile Strength | ASTM D4632 | N | 500 – 5,500 |

| CBR Puncture | ASTM D6241 | N | 1,200 – 15,000 |

| UV Resistance | ASTM D4355 | % | > 70% @ 500 hours |

| Packaging | - | - | Black PE film, paper core |

Ideal Applications for Wide-Width Fabric

This product is engineered for projects where "covering ground fast" is the priority:

-

Landfill Engineering:

Used as a protection cushion over geomembranes in vast landfill cells. The wide width minimizes the risk of construction equipment damaging the liner at seam locations.

-

Land Reclamation & Artificial Islands:

Deploying separation layers over soft marine clay or sludge across hundreds of hectares.

-

Tailings Storage Facilities (TSF):

Mining projects require heavy-duty, wide fabrics to cover immense areas securely and quickly.

-

Airport Runways & Highways:

Roadbed separation layers for multi-lane highways or airport tarmacs where continuous, uniform coverage is essential.

-

Reservoirs and Canals:

Lining large water containment structures with fewer seams to ensure better water tightness reliability.

Project Cost Analysis Example

Why Width Matters:

Imagine a 500-meter wide project site.

- Using 4m rolls: You need 125 passes (124 seams).

- Using 8m rolls: You need only 62 passes (61 seams).Result: You save 50% on sewing labor and overlap material waste!

Optimize Your Project Budget Today

Don't let inefficient material sizes slow down your construction. As a specialized Wide Width Geotextile Manufacturer, we have the capacity to supply large volumes with global shipping logistics support.

Contact us for a calculation of how much you can save by switching to 8m rolls!

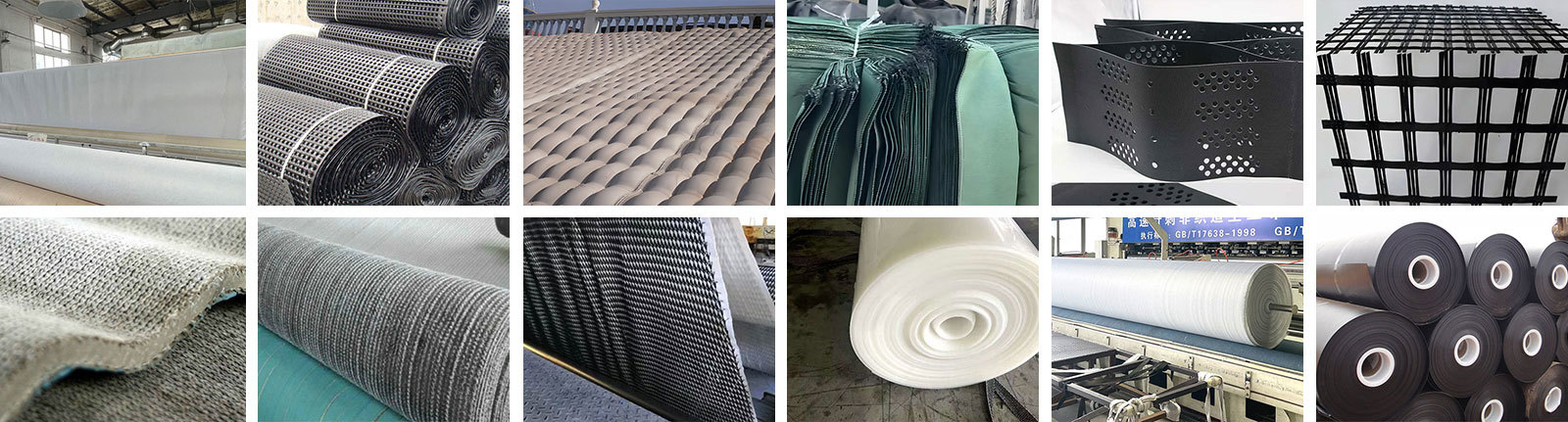

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE