Standard Certified By

Polyethylene Liner

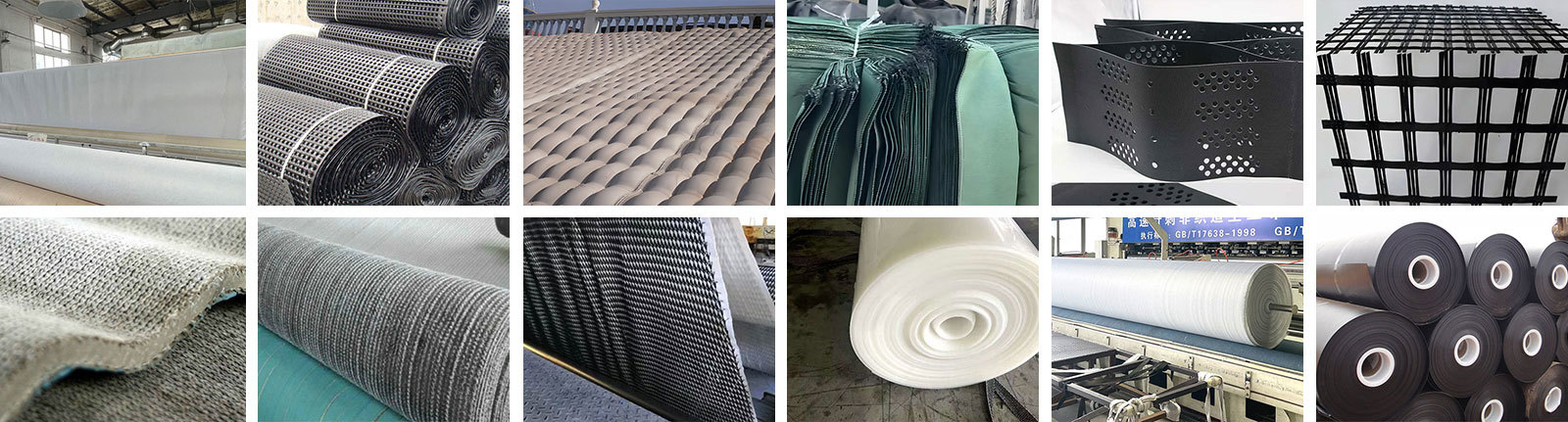

Classification :

PRODUCT DETAILS

What is Polyethylene Liner?

Polyethylene Liner is a lining made of polyethylene material. Polyethylene has excellent chemical corrosion resistance and can resist the erosion of various acids, alkalis, salts and other chemical substances. It also has good waterproof properties and can effectively prevent liquid leakage. It can be used in situations that require moisture-proof and waterproof properties.

Specification:

Black, white, green, blue etc. or according to your.

Width: 1-8m

Length: 50-150m as customized

Thickness:0.2mm-3.0mm

Color: Black, white,blue customized products can be supported according to customer needs

Keyword: Geomembrane,HDPE Geomembrane,Pond Liner,Waterproof Membrane,0.5mm Geomembrane,1.0mm Geomembrane,Geomembrane Liner,HDPE Liner,Landfill Liner,Geomembrane Liner,Shrimp Pond Liner,Tailings pond Geomembrane

What is the types of Polyethylene Liner?

Smooth HDPE geomembrane liner

Single side Textured HDPE geomembrane liner -Matte

Double side Textured HDPE geomembrane liner -Matte

Single side Textured HDPE geomembrane liner -Column Dot

Double side Textured HDPE geomembrane liner -Column Dot

What are the applications of Polyethylene Liner?

Polyethylene Liner are versatile materials that have a variety of applications in several fields, particularly where liquid or waste containment is essential. Here are some of the most common applications:

Landfills: Polyethylene Liner are often used as liners in landfills to prevent leachate, a liquid that contains environmentally harmful substances, from contaminating the groundwater.

Ponds and Lagoons: They are used as liners in decorative ponds, fish ponds, lagoons, and artificial lakes to prevent water leakage into the ground.

Reservoirs and Tanks: They are also used to line reservoirs, tanks, and other storage facilities that hold water, other liquids, or even gases.

Canals: Polyethylene Liner are often used to line canals, ditches, or other waterways to prevent erosion and water loss.

Mining: In the mining industry, they are used to line tailings ponds and heap leach pads to prevent contamination of the surrounding environment.

Agriculture: In agriculture, they can be used in irrigation ditches, farm ponds, or even to line manure lagoons.

Construction: They can be used as a moisture barrier under concrete slabs or inside basement walls to prevent moisture intrusion.

Environmental Remediation: They are used in environmental remediation projects to contain contaminated materials or to prevent contaminants from spreading to adjacent areas.

Oil and Gas industry: They can be used for secondary containment around fuel storage tanks to prevent any potential leaks from contaminating the surrounding environment.

Aquaculture: In aquaculture, Polyethylene Liner are used to line fish or shrimp ponds to maintain water quality and prevent diseases.

These are just a few examples, and the use of HDPE geomembranes can vary widely depending on the specific requirements of the project.

Performance

Chemical Resistance: The Polyethylene Liner stands out for its excellent resistance to a wide variety of chemicals, making it suitable for challenging industrial environments, including waste management and mining applications.

Weather Durability: This geomembrane displays high resilience against varying weather conditions. Its excellent UV stability and low-temperature flexibility ensure the membrane maintains integrity and performance, regardless of climatic challenges.

Impermeability: Offering superior impermeability, the Polyethylene Liner acts as a robust barrier against liquids and gases. Its leak-proof nature prevents seepage and leakage, ensuring optimal performance in containment applications.

Installation Efficiency: Despite its high-strength and durability, the Polyethylene Liner is lightweight, facilitating ease and efficiency in installation. It requires no specialized tools or intense labor, adding to its user convenience.

Longevity and Maintenance: The geomembrane's high durability ensures a long-lasting containment solution. Its smooth surface and resistance to environmental degradation reduce maintenance requirements, providing an excellent return on investment over its lifecycle.

Versatility: Polyethylene Liner is available in various thicknesses, catering to a wide range of project requirements. Whether for waste management, water storage, or industrial containment, it delivers consistent and reliable performance.

To summarize, the Polyethylene Liner performs exceptionally across all essential parameters. It offers a versatile, efficient, and reliable solution for diverse containment needs.

| Properties | Test Method | Test Value | Testing Frequency (minimum) | |||||||||||||||||

| 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50 mm | 3.00 mm | ||||||||||||||

| Thickness - (min. ave.) - mm | 0.3mm-3mm | per roll | ||||||||||||||||||

| • owest individual of 10 values - % | - 10 | |||||||||||||||||||

| Formulated Density (min. ave.) - g/cc | D 1505/ D 792 | 0.950 | 90,000 kg | |||||||||||||||||

| Tensile Properties(1)(min. ave.) | D 6693 | / | 9,000 kg | |||||||||||||||||

| Tear Resistance (min. ave.) - N | D 1004 | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg | |||||||||||

| Puncture Resistance (min. ave.) - N | D4833 | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg | |||||||||||

| Stress Crack Resistance (2) - hr. | D 5397 (App.) | 500 | per GRI GM- 10 | |||||||||||||||||

| Carbon Black Content (range) - % | D 4218⑶ | 2.0 -3.0 | 9,000 kg | |||||||||||||||||

| Carbon Black Dispersion | D 5596 | note (4) | 20,000 kg | |||||||||||||||||

| Oxidative Induction Time (OIT) (5) (min. ave.) | / | 90,000 kg | ||||||||||||||||||

| (a) Standard OIT - min. | D3895 | 100 | ||||||||||||||||||

| (b) High Pressure OIT - min. | D5885 | 400 | ||||||||||||||||||

| Oven Aging at 85°C (5) (6) | D5721 | / | per each formulation | |||||||||||||||||

| (a)Standard OIT (min. ave.) - % retained after 90 | D3895 | 55 | ||||||||||||||||||

| (b) High Pressure OIT (min. ave.) - % retained after 90 days | D5885 | 80 | ||||||||||||||||||

| UV Resistance (7) | D 7238 | / | per each formulation | |||||||||||||||||

| (a) Standard OIT (min. ave.) | D 3895 | N. R.(8) | ||||||||||||||||||

| (b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | D5885 | 50 | ||||||||||||||||||

| (1) Machine direction (MD) and cross machine direction (XMD) average values should be on the basis of 5 test specimens each direction Yield elongation is calculated using a gage length of 33 mm Break elongation is calculated using a gage length of 50 mm (2) The yield stress used to calculate the applied load for the SP-NCTL test should be the manufacturer ’s mean value via MQC testing. (3) Other methods such as D 1603 (tube furnace) or D 6370 (TGA) are acceptable if an appropriate correlation to D 4218 (muffle furnace) can be established. (4) Carbon black dispersion (only near spherical agglomerates) for 10 different views:9 in Categories 1 or 2 and 1 in Category 3 (5) The manufacturer has the option to select either one of the OIT methods listed to evaluate the antioxidant content in the geomembrane. (6) It is also recommended to evaluate samples at 30 and 60 days to compare with the 90 day response. (7) The condition of the test should be 20 hr. UV cycle at 75 °C followed by 4 hr. condensation at 60 °C. (8) Not recommended since the high temperature of the Std-OIT test produces an unrealistic result for some of the antioxidants in the UV exposed samples. (9) UV resistance is based on percent retained value regardless of the original HP-OIT value. | ||||||||||||||||||||

Packaging And Delivery

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE