Standard Certified By

Lake cement blanket

Classification :

PRODUCT DETAILS

1. What is Lake cement blanket?

Lake cement blanketis a new class of geosynthetic material with a wide range of geotechnical applications. It is also called Concrete covers or Cement blanket.

GCCM is a flexible concrete-impregnated fabric that hardens on hydration to form a thin, durable, waterproof and fire-resistant concrete layer. It consists of a 3-dimensional fibre matrix containing a high early-strength concrete mix, and is also a blanket material made of geotextile and concrete dry mix. After laying, it can form a concrete protective layer with a certain hardness and thickness through watering and curing.

Specifically, GCCM includes a 3-dimensional fibre matrix with a specially formulated dry cementitious mix. In engineering applications, it mainly plays the roles of reinforcement, strengthening and anti-seepage.

Specification of GCCM

- Width: 1m-4m or follow customers' demand

- Length: 5-50m or follow customers' request

- Weight: 8-20kg per square meter (common weights also include 15KG, 12KG, 10KG, 8KG)

- Thickness: Common options are 12mm, 10mm, 8mm, 5mm

- Color: Grey (Customizable)

- Note: Special specifications and sizes are negotiable.

2. What are the Types of GCCM?

GCCM is divided into two types according to material and process, namely three-dimensional woven fabric (G type) and needle-punched composite type (D type).

- G-Type Cement blanket: Also known as three-dimensional mesh-filled concrete cement blanket, it is a blanket material formed by filling concrete dry powder mixture into a three-dimensional mesh, then sealing it with high-strength fabric or anti-seepage material.

- D-Type Cement blanket: Also called mechanical composite cement blanket, it consists of upper and lower layers of fabric and a middle concrete dry powder layer. These three layers are compounded together through mechanical actions (such as needle punching, sewing) to form a blanket material.

3. What are the Applications of GCCM?

GCCM mainly plays the roles of reinforcement, strengthening and anti-seepage in the following engineering applications:

- Water conservancy projects: Rivers, scenic lakes, canals, etc.

- Transportation projects: Highways, railways, bridges, subways.

- Agricultural fields: Aquaculture, animal husbandry, agricultural irrigation.

- Military fields: Tents, flood control and rescue, soft base treatment.

- Environmental engineering: Wind and sand fixation, landfills, sewage treatment plants.

- Marine engineering: Submarine optical cables, bridge piers, reclamation slope protection.

Its typical application scenarios also include ditch lining, slope stabilization, shoreline armor, secondary berm protection, culvert invert protection, and geosynthetic liner protection.

4. Performance of GCCM

- Strong: GCCM is a flexible cement-based composite material with certain toughness. It has low requirements on the foundation and is not easy to crack. Its strong fibre reinforcement absorbs any impact affecting infrastructure, which prevents cracking and ensures complete safety.

- Durable: GCCM is 5x more abrasion-resistant than standard concrete, has excellent chemical resistance and good weathering performance, and will not degrade under UV radiation.

- Flexible: GCCM has good drape characteristics, can closely follow the ground profile and fit around existing infrastructure. Unset GCCM can be cut or tailored using basic hand tools.

- Good construction adaptability: GCCM can be directly used for underwater operations, and construction is not affected by rainy weather. It has excellent frost resistance, corrosion resistance and scouring resistance, with a short construction period that is simple and fast.

| Item | Unit | Technical requirements for ordinary type | Technical requirements for anti-seepage type | ||

| 15Kg | 8Kg | 15Kg | 8Kg | ||

| Mass per unit area | Kg/㎡ | Not less than 90% of the specified value | Not less than 90% of the specified value | Not less than 90% of the specified value | Not less than 90% of the specified value |

| Tensile strength | KN/m | ≥20 | ≥12 | ≥20 | ≥12 |

| Flexural strength | Mpa | ≥3.0 | ≥1.0 | ≥2.0 | ≥0.7 |

| Impact resistance | No visible cracks or damage | No visible cracks or damage | No visible cracks or damage | No visible cracks or damage | |

| Waterproofness | Micro-seepage | Micro-seepage | Reserved overlap edge No wet marks or water drops on the back of the specimen | Reserved overlap edge No wet marks or water drops on the back of the specimen | |

| Freeze-thaw resistance(50 times) | % | ≤2 | ≤2 | ≤2 | ≤2 |

| Acid and alkali resistance (Strength retention value) | % | ≥80 | ≥80 | ≥80 | ≥80 |

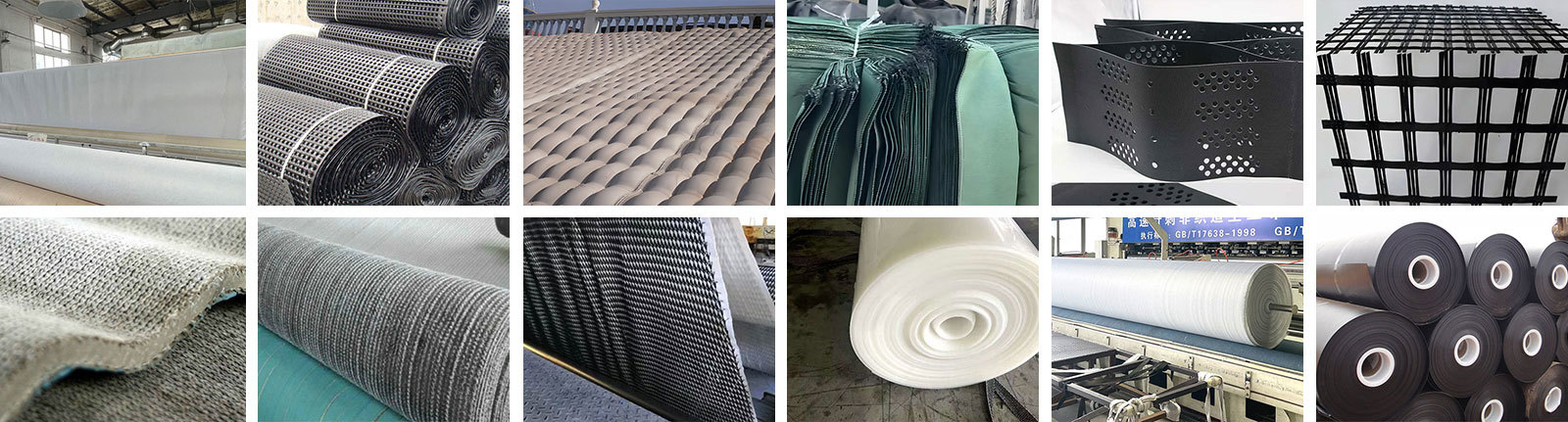

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE