Standard Certified By

PET Long Fiber Geotextile

Classification :

PRODUCT DETAILS

What is the Polyester filament Nonwoven Geotextile ?

The specifications of polyester filament nonwoven geotextile can be selected from 80-800 g/m2, abbreviated as “PET filament nonwoven geotextile”. In addition to having good mechanical properties, PET filament nonwoven geotextile also has good longitudinal and transverse drainage performance, good elongation performance, and high chemical stability properties such as biological and aging resistance. It is mainly used for road reinforcement and crack repair to protect soil from loss; Used for filter layer for tailings dam body; Used as an isolation layer between road, airport, railway masonry and foundation; Used for drainage of dam body and concrete lake surface; Used for drainage and other purposes in tunnel lining engineering.

Specification:

Length:50-300m as customized

Weight:100-1200g/m2

Color:Black, white,customized products can be supported according to customer needs

PET filament nonwoven geotextile can be used to increase the stability of gravel slopes and reinforced soil, prevent soil erosion and frost damage to soil at low temperatures.

PET filament nonwoven geotextile can be used as a filter layer around drainage pipes.

PET filament nonwoven geotextile can be used to strengthen weak foundations in projects such as highways, railways, embankments, airports, and ports.

reinforcement and other functions, can adapt to uneven base course, can resist external force damage during construction, creep is small, and can still maintain its original function under long term load.

Permeability and planar drainage: PET filament nonwoven geotextile is thick and formed, with good planar drainage and vertical permeability, and can still maintain this performance after many years.

Creep resistance: PET filament nonwoven geotextile has better creep resistance than other geotextiles, therefore it has good long term performance. It can withstand the erosion of common

chemical substances in soil and the corrosion of gasoline, diesel, etc.

Ductility: PET filament nonwoven geotextile has good elongation under certain stress, allowing it to adapt to uneven and irregular base surfaces.

| Properties | Unit | ASTM standard | Test Range | ||||||||||

| Machanical spec | Unit Weight | g/sqm | ASTM D 5261 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Ultimate Tensile Strength,MD | KN/m | ASTM D4595 | 7 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 45 | |

| Ultimate Tensile Strength,TD | KN/m | ASTM D4595 | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 | |

| Tensile Elongation | % | ASTM D4595 | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | |

| Grab Tensile Strength,MD | N | ASTM D4632 | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 | |

| Grab Tensile Strength,TD | N | ASTM D4632 | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 | |

| Grab Elongation | % | ASTM D4632 | 45 | 45 | 50 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Trapezoidal Tear Strength,MD | N | ASTM D4533 | 160 | 300 | 350 | 410 | 490 | 540 | 630 | 710 | 770 | 920 | |

| Trapezoidal Tear Strength,TD | N | ASTM D4533 | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 | |

| CBR Puncture Strength | N | ASTM D6241 | 1000 | 1500 | 2300 | 2700 | 3200 | 3600 | 4400 | 4500 | 5800 | 6900 | |

| Hydraulic spec | Water Flow Q100 | L/m2/s | ASTM D4491 | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

| Apparent Opening Size | mm | ASTM D4751 | 0.12 | 0.11 | 0.11 | 0.1 | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | |

| Roll size | ThicKNess | mm | ASTM D5199 | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

| Width | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||

| Length | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 | ||

Packaging And Delivery

PROJECT CASES

APPLICATION AREAS

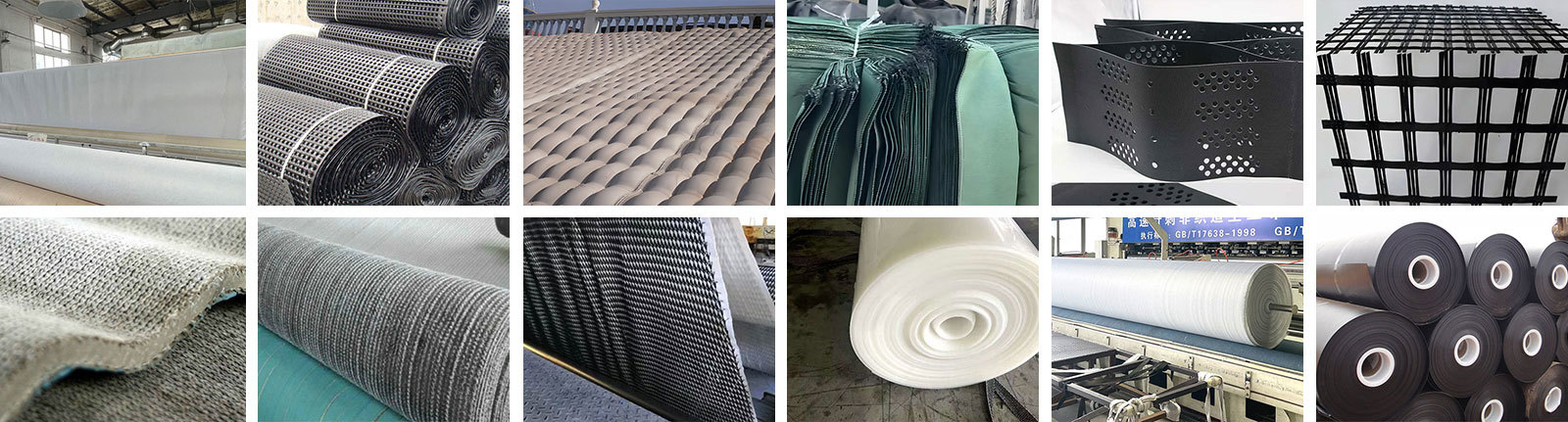

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE