Standard Certified By

Slope protection composite geomembrane

Classification :

PRODUCT DETAILS

What is Composite Slope protection composite geomembrane?

Composite Slope protection composite geomembrane is a geosynthetic anti-seepage material composed of plastic film as the anti-seepage substrate and nonwoven fabric. Its anti-seepage performance mainly depends on the anti-seepage performance of the plastic film. The plastic films used for anti-seepage applications both domestically and internationally mainly include polyvinyl chloride (PVC), polyethylene (HDPE, LDPE, LLDPE), and ethylene/vinyl acetate copolymer (EVA). The most common types of composite Slope protection composite geomembranes are made from a combination of high-density polyethylene (HDPE) and polypropylene (PP). They are polymer chemical flexible materials with small specific gravity, strong extensibility, high adaptability to deformation, corrosion resistance, low temperature resistance, and good frost resistance.

What are the Types of Composite Slope protection composite geomembranes?

There are two common types of composite Slope protection composite geomembranes:

1.Single-layer composite Slope protection composite geomembranes: Single-layer composite Slope protection composite geomembranes are made from a single layer of material that has been reinforced with another material. For example, a single-layer composite Slope protection composite geomembrane could be made from a layer of HDPE that has been reinforced with a layer of fiberglass.

2.Double-layer composite Slope protection composite geomembranes: Double-layer composite Slope protection composite geomembranes are made from two separate layers of material that are bonded together. For example, a double-layer composite Slope protection composite geomembrane could be made from two layers of HDPE that are bonded together with a layer of adhesive.

The type of composite Slope protection composite geomembrane that is best for a particular application will depend on the specific requirements of the project. For example, a single-layer composite Slope protection composite geomembrane may be sufficient for a project where the Slope protection composite geomembrane will not be exposed to high levels of stress, while a double-layer composite Slope protection composite geomembrane may be necessary for a project where the Slope protection composite geomembrane will be exposed to more severe conditions.

Composite Slope protection composite geomembranes can also be categorized by the combination of geotextiles and Slope protection composite geomembranes:

- One geotextile and one Slope protection composite geomembrane

- Two geotextiles and one Slope protection composite geomembrane

- Multiple geotextiles and multiple Slope protection composite geomembranes

Color options for composite Slope protection composite geomembranes include black, white, or customized colors.

It is important to note that there are many different variations of composite Slope protection composite geomembranes available on the market. The specific properties of a composite Slope protection composite geomembrane will depend on the materials that are used to make it and the manufacturing process. It is important to consult with a qualified manufacturer to select the right composite Slope protection composite geomembrane for your specific application.

What are the Applications of Composite Slope protection composite geomembrane?

Composite Slope protection composite geomembrane is a high-performance Slope protection composite geomembrane that is ideal for a variety of applications, including:

- Landfill liners: Composite Slope protection composite geomembrane can be used to create effective landfill liners that prevent leachate from leaking into the environment.

- Dams and levees: Composite Slope protection composite geomembrane can be used to create dams and levees that protect against flooding.

- Aquaculture ponds: Composite Slope protection composite geomembrane can be used to create aquaculture ponds that protect fish and other aquatic life from contaminants.

- Wastewater treatment systems: Composite Slope protection composite geomembrane can be used to create wastewater treatment systems that prevent pollutants from entering the environment.

- Recreational facilities: Composite Slope protection composite geomembrane can be used to create recreational facilities, such as swimming pools and water parks, that are safe and sanitary.

Composite Slope protection composite geomembrane is a reliable and high-performance Slope protection composite geomembrane that is backed by a 20-year warranty. If you are looking for a Slope protection composite geomembrane that can provide years of reliable service, then composite Slope protection composite geomembrane is the right choice for you.

Performance of Composite Slope protection composite geomembrane

Composite Slope protection composite geomembrane is a high-performance Slope protection composite geomembrane that offers a number of advantages, including:

- Increased strength and durability: The combination of HDPE and PP in composite Slope protection composite geomembrane provides increased strength and durability. This makes it ideal for applications where it will be exposed to harsh environmental conditions, such as UV radiation, chemicals, and temperature extremes.

- Reduced permeability: Composite Slope protection composite geomembrane is highly impermeable, meaning it can be used to create effective barriers against water, air, and other liquids.

- Easy to install: Composite Slope protection composite geomembrane is easy to install using a variety of methods, including welding, heat bonding, and mechanical fastening.

- Long lifespan: Composite Slope protection composite geomembrane has a long lifespan of up to 50 years. This makes it a cost-effective solution for a variety of applications.

Here are some of the performance tests that composite Slope protection composite geomembrane has passed:

- Tensile strength: Composite Slope protection composite geomembrane has a tensile strength of 20 MPa. This means that it can withstand a force of 20,000 Newtons per square meter before it breaks.

- Tear resistance: Composite Slope protection composite geomembrane has a tear resistance of 100 N/mm. This means that it can withstand a force of 100 Newtons before it tears.

- Water permeability: Composite Slope protection composite geomembrane has a water permeability of 1 x 10^-10 m/s. This means that it is virtually impermeable to water.

- Chemical resistance: Composite Slope protection composite geomembrane is resistant to a wide range of chemicals, including acids, bases, and solvents.

- UV resistance: Composite Slope protection composite geomembrane is resistant to UV radiation. This means that it will not degrade when exposed to sunlight.

- Temperature range: Composite Slope protection composite geomembrane can withstand temperatures of -40°C to +80°C. This makes it suitable for use in a variety of climates.

Composite Slope protection composite geomembrane is a reliable and high-performance Slope protection composite geomembrane that has been tested and proven to meet the requirements of a variety of applications. If you are looking for a Slope protection composite geomembrane that can provide years of reliable service, then composite Slope protection composite geomembrane is the right choice for you.

| Project | Unit weight g/m² | ||||||||

| 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | ||

| The fracture strength of nominal /(KN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Longitudinal and transverse rupture strength /(KN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Vertical and horizontal standard strength corresponding elongation | 30~100 | ||||||||

| CBR breaks through powerfully /KN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| Vertical and horizontal tearing strength /KN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic pressure /MPa | According to the table below | ||||||||

| Peel Strength N/cm | 6 | ||||||||

| Coefficient of vertical permeablity/(cm/s) | According to design or contract requirements | ||||||||

| Width deviation % | -1.0 | ||||||||

| Item | Thickness of Slope protection composite geomembrane /mm | ||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | ||

| Hydrostatic pressure/MPa ≥ | Geotextile+Slope protection composite geomembrane+Geotextile | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 |

| Geotextile+Slope protection composite geomembrane+Geotextile | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | |

Packaging And Delivery

PROJECT CASES

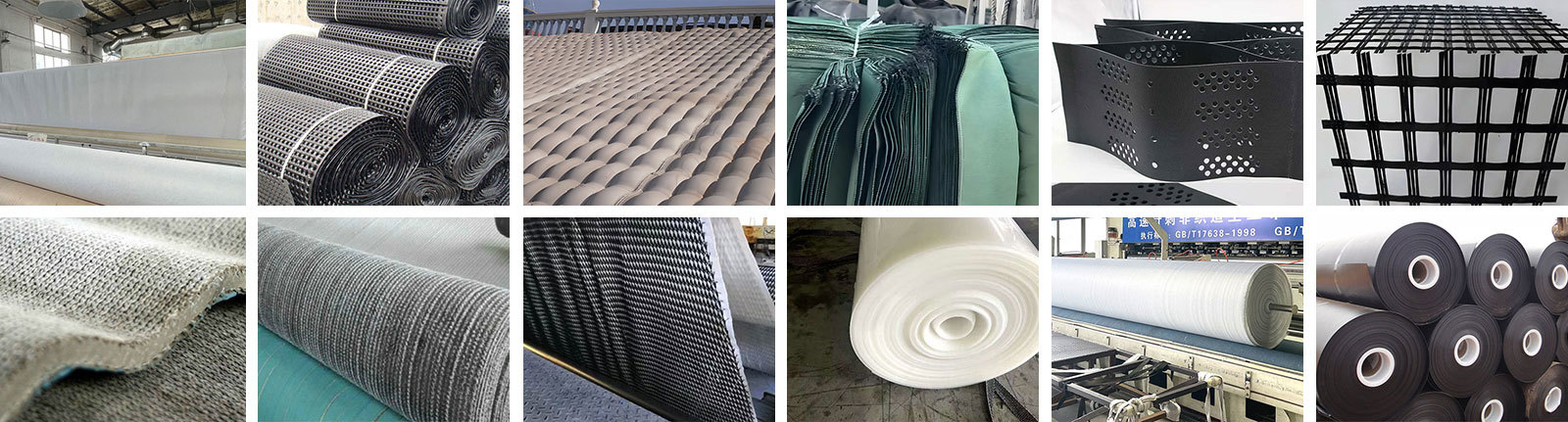

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE