Maximizing Road Durability: The Role of Composite Geogrids in Soil Stabilization

Release time:

2026-01-08

Improve road durability and reduce maintenance costs. Learn how composite geogrids combine reinforcement and filtration to enhance soil stability in infrastructure projects.

Infrastructure projects often face the challenge of weak subgrade soils. Traditional methods like deep excavation are costly and time-consuming. This is where Composite Geogrids—a combination of a reinforcing grid and a non-woven geotextile—become a game-changer for engineers worldwide.

The Dual-Function Advantage

Unlike standard geogrids, composite materials provide two critical functions in one layer:

Reinforcement: The grid interlocks with aggregate particles to distribute heavy traffic loads over a wider area, reducing rutting and cracks.

Filtration and Drainage: The integrated geotextile prevents fine soil particles from mixing with the expensive aggregate layer while allowing water to pass through freely.

How it Reduces Project Costs

Reduced Material Usage: By enhancing the load-bearing capacity of the soil, you can reduce the required thickness of the aggregate base by up to 30%.

Extended Service Life: Roads reinforced with geosynthetics exhibit significantly fewer structural failures, leading to lower long-term maintenance budgets.

Faster Installation: Combining two materials into one product speeds up the laying process on-site.

Typical Applications

Temporary access roads over soft ground.

High-load industrial pavements and parking lots.

Railway trackbed stabilization.

Summary

As the demand for sustainable and resilient infrastructure grows, composite geogrids offer a cost-effective and environmentally friendly solution. For your next road project, consider switching to high-performance geosynthetics to ensure structural integrity from the ground up.

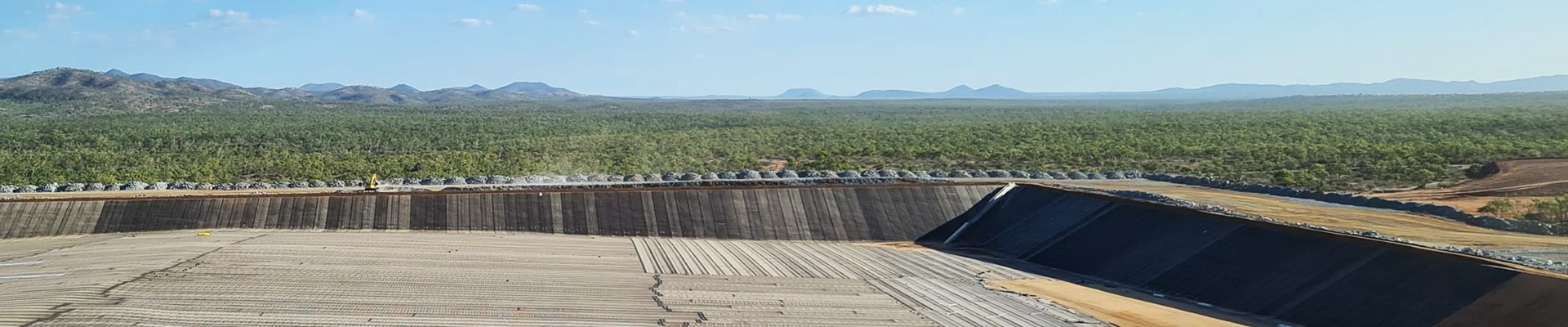

PROJECT CASES