Standard Certified By

Geosynthetic Clay Liners (GCL) Manufacturer & Supplier | Longxiang New Materials

Classification :

PRODUCT DETAILS

1. Product Overview

Longxiang New Materials is a leading manufacturer and supplier of high-quality Geosynthetic Clay Liners (GCLs). Our GCLs are high-performance needle-punched environmental reinforced composites which combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier.

Designed to replace traditional compacted clay liners (CCL), our GCL products offer superior hydraulic performance and are ideal for waste management, mining, and water containment projects. As a direct factory, we provide wholesale pricing and custom dimension solutions to meet ASTM standards.

2. Key Features & Benefits

Self-Sealing Capability: The sodium bentonite core swells when hydrated, effectively self-sealing minor punctures during installation.

Superior Impermeability: Offers better hydraulic performance than meters of compacted clay, ensuring maximum leak protection.

Cost-Effective Installation: Lightweight and easy to deploy, reducing transportation costs and installation time compared to traditional soil barriers.

Shear Strength: Needle-punched reinforcement locks the geotextiles together, providing excellent internal shear resistance for slope applications.

Eco-Friendly: Made from natural materials, safe for environmental containment projects.

3. Applications

Our Geosynthetic Clay Liners are engineered for a wide range of containment applications:

Landfill Liners & Caps: Base liners and final cover systems for municipal solid waste (MSW) landfills.

Mining Solutions: Heap leach pads and tailings dams.

Water Management: Artificial lakes, canals, reservoirs, and storm-water impoundments.

Environmental Protection: Secondary containment for fuel storage tanks and groundwater protection.

Transportation: Waterproofing for highway and railway embankments.

4. Technical Specifications

Standard GCL Specifications (Reference Data):

| Properties | Test Method | Unit | Typical Value |

|---|---|---|---|

| Bentonite Mass / Unit Area | ASTM D5993 | g/m² | ≥ 4000 |

| Grab Tensile Strength | ASTM D6768 | N/10cm | ≥ 600 |

| Peel Strength | ASTM D6496 | N/10cm | ≥ 65 |

| Permeability | ASTM D5887 | m/s | $\le 5 \times 10^{-11}$ |

| Swell Index | ASTM D5890 | ml/2g | ≥ 24 |

| Roll Dimensions | - | m | 5.8m (W) x 30m (L) |

Note: We offer customizable roll widths and lengths to suit specific project requirements.

5. Why Choose Longxiang New Materials as Your GCL Supplier?

Direct Factory Price: Eliminate the middleman. Get competitive pricing directly from our manufacturing facility.

Quality Assurance: Every roll is tested in our in-house laboratory to ensure compliance with GRI-GCL3 and ASTM standards.

Global Logistics: We have extensive experience in exporting to destinations worldwide, ensuring timely delivery.

Technical Support: Our engineering team provides installation guidance and technical data support for your specific projects.

6.FAQ

- Q: What is the difference between GCL and Geomembrane?

A: A Geosynthetic Clay Liner (GCL) uses bentonite clay for self-sealing waterproofing, while a Geomembrane is a plastic sheet (like HDPE) that acts as a physical barrier. Often, they are used together in a "composite liner system" for maximum protection.

- Q: How does GCL work?

A: When the sodium bentonite clay inside the GCL comes into contact with water, it hydrates and swells. Since it is confined between geotextiles, this swelling creates a dense, highly impermeable barrier that prevents liquid leakage.

- Q: What is the typical lifespan of GCL?

A: When properly installed and covered, GCLs are designed to last for decades. Natural bentonite does not degrade over time, making it a long-term solution for containment.

7. Call to Action

Ready to get a quote?

Contact our team today for a free sample and the latest price list for Geosynthetic Clay Liners.

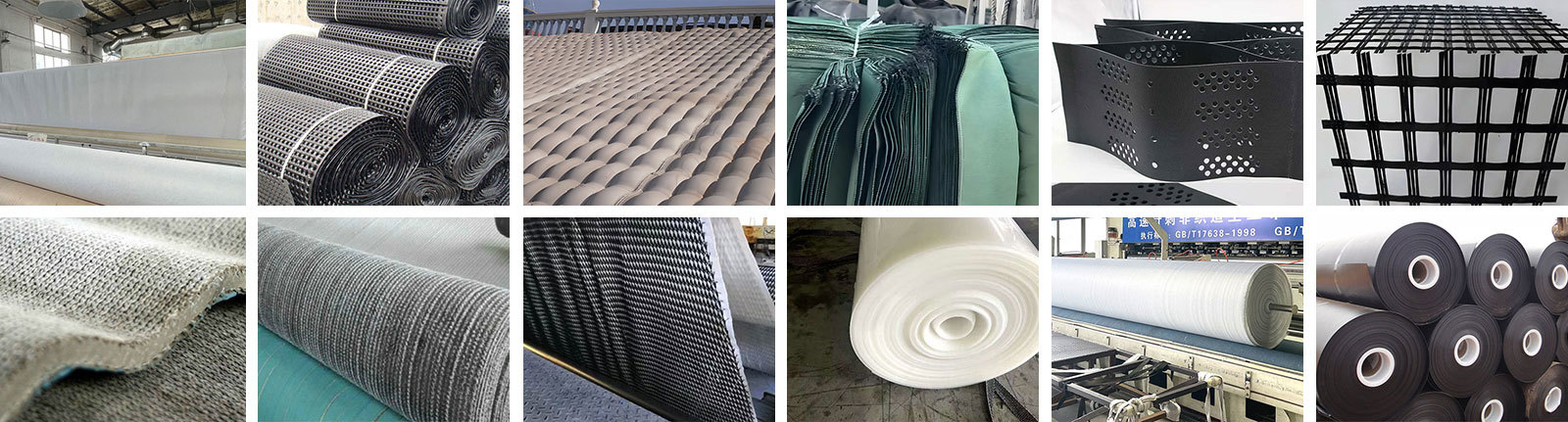

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE