Standard Certified By

1.5mm ASTM GRI-GM13 HDPE Liner for Biogas Digester Cover and Methane Capture

Classification :

PRODUCT DETAILS

1. Product Overview

Seal Your Energy. Stop Odor. Power Your Operations.

Our 1.5mm ASTM GRI-GM13 HDPE Geomembrane is the industry-leading solution for Biogas Digester Covers and Anaerobic Digester (AD) Systems. This high-specification liner is not just a cap; it is a critical component for Methane Capture and renewable energy generation. Engineered to be gas-tight and highly resistant to the chemical challenges of biogas (including H2S), our 1.5mm cover ensures maximum energy recovery and eliminates foul odors from livestock and municipal waste treatment facilities.

2. Key Features

-

Exceptional Gas Impermeability: The dense 1.5mm HDPE structure provides an extremely low permeability coefficient, effectively preventing the escape of valuable Methane (CH4) and preventing disruptive Oxygen (O2) intrusion.

-

H2S Chemical Resistance: HDPE naturally resists the corrosive effects of Hydrogen Sulfide (H2S) often present in raw biogas, ensuring the cover's long-term integrity where other materials may quickly degrade.

-

ASTM GRI-GM13 Certified: Fully compliant with the most stringent global standards, guaranteeing the quality required for demanding biogas and waste-to-energy projects.

-

Superior UV & Weather Resistance: Designed to be 100% exposed to the elements. High-grade carbon black ensures long-term UV and Ozone resistance, offering a service life of 15+ years.

-

Odor & Pest Control: Acts as a complete physical barrier to eliminate fugitive odors and deter pest intrusion, enhancing the operational compliance of the facility.

3. Detailed Description

The Role of the Geomembrane in Biogas Systems

The cover on an Anaerobic Digester (AD) must handle significant dynamic stress: wind uplift, snow load, and internal gas pressure fluctuations. The 1.5mm (60 mil) HDPE thickness offers the ideal balance:

-

Strength for Tensioning: Robust enough to be tensioned around anchor trenches without tearing or stress-cracking.

-

Flexibility for Floating Covers: Sufficiently flexible for Floating Biogas Covers, allowing it to rise and fall with the liquid level in the digester tank or lagoon.

-

Weld Integrity: Provides sufficient material for high-quality, continuous Double-Track Hot Wedge Welding, which is essential for proving the cover is gas-tight through air pressure testing.

Maximizing Methane Capture Efficiency

Every molecule of Methane not captured is a loss of potential revenue. By using a certified GRI-GM13 liner, you guarantee the consistency and density needed for maximum Methane Capture. This enables biogas facilities (such as those converting dairy manure or municipal sludge) to efficiently produce Renewable Natural Gas (RNG) or generate electricity.

4. Technical Specifications

| Property | Test Method (ASTM) | Unit | Value (GRI-GM13 Standard) |

| Product | - | - | Biogas Cover Grade HDPE |

| Thickness (Nominal) | ASTM D5199 | mm (mil) | 1.50 mm (60 mil) |

| Density | ASTM D792 | g/cm³ | ≥ 0.940 |

| Tensile Strength (Yield) | ASTM D6693 | N/mm | ≥ 22 |

| Tear Resistance | ASTM D1004 | N | ≥ 187 |

| Puncture Resistance | ASTM D4833 | N | ≥ 480 |

| Stress Crack Resistance (ESCR) | ASTM D5397 | Hours | ≥ 500 |

| Carbon Black Content | ASTM D1603 | % | 2.0 - 3.0 |

| Roll Width | - | m | Up to 8.0m |

5. Application Areas

-

Anaerobic Digestion (AD) Lagoons: Covers for large agricultural manure/sludge pits.

-

Wastewater Treatment Plants: Primary and secondary clarifier covers for odor control and gas harvesting.

-

Biogas Storage Domes: External flexible cover for gas storage tanks.

-

Water Reservoir Covers: Odor control and evaporation suppression in large storage ponds.

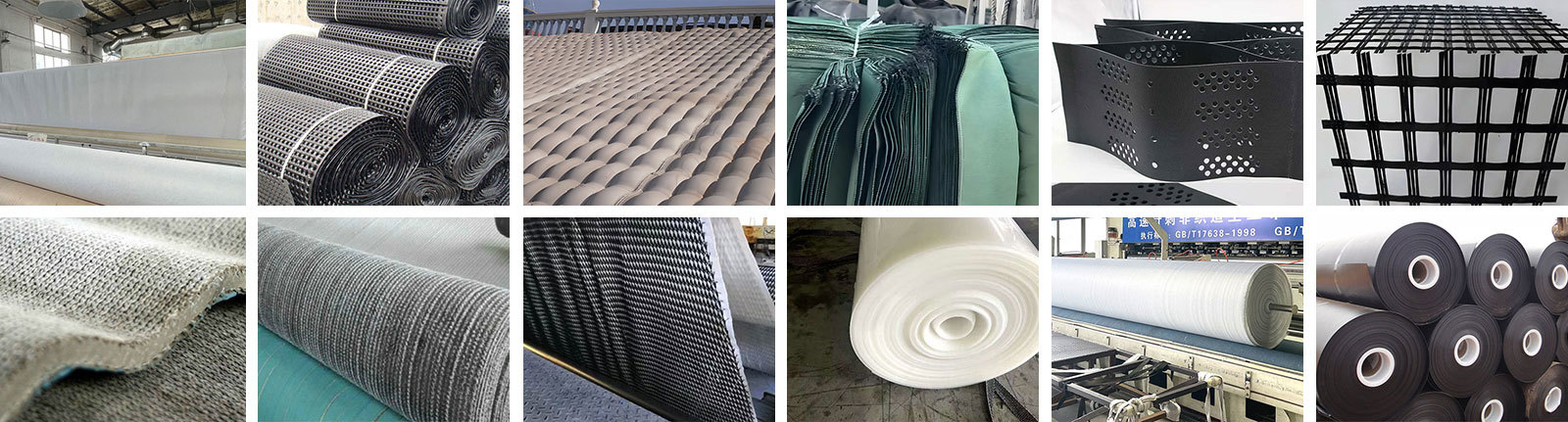

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE