Standard Certified By

2.0mm High Density Polyethylene Geomembrane for Mining Heap Leach Pad

Classification :

PRODUCT DETAILS

1. Product Overview

Maximize Recovery. Minimize Loss.

Our 2.0mm High Density Polyethylene (HDPE) Geomembrane is the heavy-duty champion for the mining industry. Engineered specifically for Heap Leach Pads, this 80 mil liner provides the ultimate physical barrier against the immense weight of stacked ore and the corrosive nature of leaching solutions. By ensuring zero leakage of the Pregnant Leach Solution (PLS), we help mining operations maximize their yield of gold, copper, and other valuable metals while adhering to strict environmental regulations.

2. Key Features

-

Extreme Puncture Resistance: The extra-thick 2.0mm (80 mil) profile offers nearly 30% more puncture resistance than standard 1.5mm liners, critical for surviving jagged ore and rough mine subgrades.

-

Superior Chemical Stability: Chemically inert to aggressive mining agents, including Cyanide (for gold/silver) and Sulfuric Acid (for copper/nickel), ensuring the liner won't degrade over the mine's lifecycle.

-

High Load Bearing: Designed to withstand the massive static and dynamic loads of high-altitude ore stacking and heavy mining machinery traffic.

-

Stress Crack Resistance (ESCR): Exceeds ASTM GRI-GM13 standards (>500 hours), guaranteeing durability against environmental stress and temperature fluctuations in harsh mining climates.

-

Friction Performance: Available in Double-Sided Textured finish to ensure the stability of the ore heap and prevent slope failures.

3. Detailed Description

The Critical Foundation of Heap Leaching

In heap leaching, the liner system is the most valuable asset. A failure in the liner means the loss of dissolved metals into the ground. Our 2.0mm HDPE Geomembrane acts as the primary containment layer. It is thick enough to resist the "point loads" exerted by sharp rocks at the bottom of the heap, ensuring that every drop of the chemical solution is directed to the collection ponds.

Why 2.0mm (80 mil) for Mining?

While 1.5mm is common for landfills, 2.0mm is the standard for Mining.

-

Physical Abuse: Mining sites involve heavy haul trucks and dozers. The 2.0mm thickness provides a safety factor against installation damage and operational stress.

-

Longevity: Mining projects often last decades. The thicker cross-section contains more antioxidants and stabilizers, resisting oxidative induction and UV degradation in high-altitude, high-UV environments (like the Andes or African deserts).

Tailored for Copper, Gold, and Uranium Mines

Whether you are leaching Copper oxide ores with sulfuric acid or Gold ores with cyanide, our HDPE resin is selected for its broad-spectrum chemical resistance. It effectively isolates hazardous chemicals from the groundwater, ensuring your mine remains compliant with international environmental standards.

4. Technical Specifications

| Property | Test Method (ASTM) | Unit | Value (GRI-GM13) |

| Product Name | - | - | Mining Grade HDPE Geomembrane |

| Thickness | ASTM D5199 | mm (mil) | 2.00 mm (80 mil) |

| Density | ASTM D792 | g/cm³ | ≥ 0.940 |

| Tensile Strength (Yield) | ASTM D6693 | N/mm | ≥ 29 |

| Tensile Strength (Break) | ASTM D6693 | N/mm | ≥ 53 |

| Puncture Resistance | ASTM D4833 | N | ≥ 640 (Crucial for Mining) |

| Tear Resistance | ASTM D1004 | N | ≥ 249 |

| ESCR (Stress Crack) | ASTM D5397 | Hours | ≥ 500 |

| Carbon Black Content | ASTM D1603 | % | 2.0 - 3.0 |

| Roll Width | - | m | 7.0m / 8.0m (Fewer seams) |

5. Application Areas

-

Heap Leach Pads: Primary liners for Gold, Silver, Copper, and Uranium ore leaching.

-

Tailings Storage Facilities (TSF): Lining tailings dams to prevent acid mine drainage (AMD).

-

Process Solution Ponds: Pregnant Leach Solution (PLS) and Barren ponds.

-

Emergency Spillways: Secondary containment for accidental overflows.

-

Mine Closure: Capping material for reclaiming old mine sites.

We recommend using a heavy-duty (e.g., 800g/m²) Nonwoven Geotextile to cushion the liner against sharp ore.

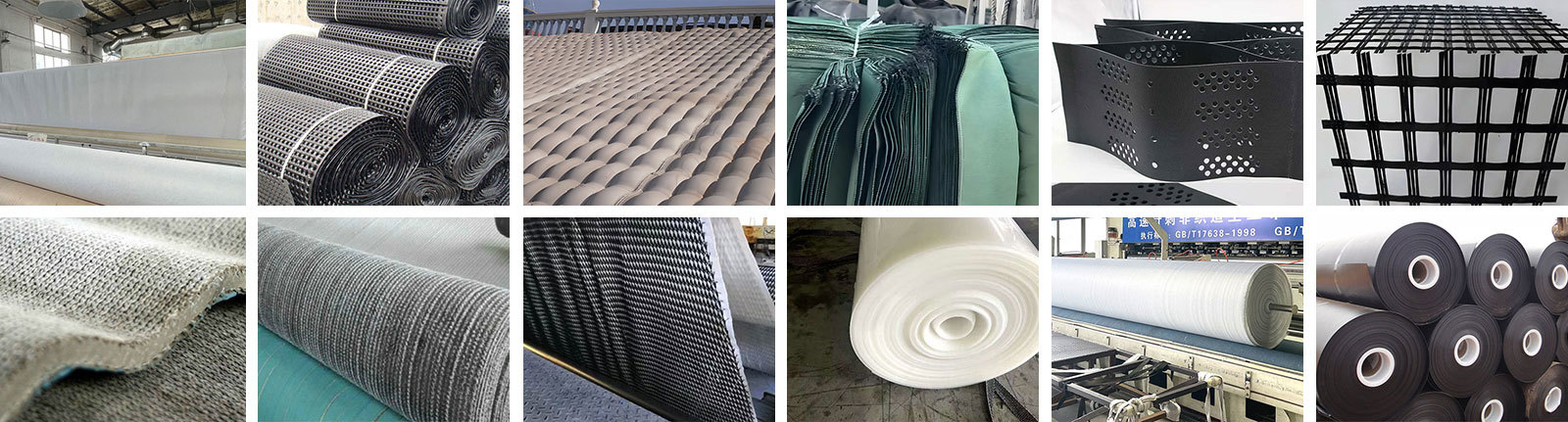

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE