Standard Certified By

Heavy Duty PET/PP Woven Geotextile | High Tensile Strength (20kN - 100kN) for Civil Engineering

Classification :

PRODUCT DETAILS

1.Product Overview

Engineered for the most demanding civil engineering projects, our Heavy Duty Woven Geotextile series offers superior soil reinforcement and stabilization solutions. Available in both High-Tenacity Polypropylene (PP) and High-Modulus Polyester (PET) yarns, this fabric is designed to withstand high tensile loads ranging from 20kN/m up to 100kN/m (and higher upon request).

Whether you are reinforcing weak subgrades for highway construction or stabilizing steep embankments, our woven geotextiles provide the critical strength, low elongation, and durability required to extend the lifespan of your infrastructure.

2.Key Features

High Tensile Strength: Robust mechanical properties with strength grades of 20kN, 40kN, 60kN, 80kN, and 100kN/m.

Dual Material Options:

PP (Polypropylene): Excellent chemical resistance (acid/alkali) and cost-effectiveness.

PET (Polyester): Superior creep resistance and high modulus for long-term structural loads.

Low Elongation: Limits soil deformation under heavy stress, ensuring structural integrity.

Durability: UV-stabilized and resistant to biological degradation, rot, and naturally occurring soil chemicals.

Hydraulic Performance: Woven structure allows for controlled water permeability while preventing soil particle migration.

3.Technical Specifications

We offer a full range of specifications to meet ASTM and ISO standards.

| Property | Test Method | Unit | WG-40 (PP/PET) | WG-60 (PP/PET) | WG-80 (PP/PET) | WG-100 (PP/PET) |

|---|---|---|---|---|---|---|

| Tensile Strength (MD) | ASTM D4595 | kN/m | 40 | 60 | 80 | 100 |

| Tensile Strength (CD) | ASTM D4595 | kN/m | 40 | 60 | 80 | 100 |

| Elongation at Break | ASTM D4595 | % | < 15% | < 15% | < 12% | < 10% |

| CBR Puncture | ASTM D6241 | kN | 4.5 | 6.5 | 8.5 | 10.5 |

| UV Resistance (500h) | ASTM D4355 | % | > 70% | > 70% | > 70% | > 70% |

| Standard Roll Width | - | m | 3.8m - 6.0m | 3.8m - 6.0m | 3.8m - 6.0m | 3.8m - 6.0m |

(Note: Custom specifications are available based on project requirements.)

4.Which Material Should You Choose: PET vs. PP?

Understanding your project environment is key to selecting the right woven geotextile:

Choose PP Woven Geotextile (Polypropylene) when:

Your project involves standard soil stabilization (roads, driveways).

The soil environment is highly acidic or alkaline (pH > 10).

Cost-efficiency is a primary concern.

Choose PET Woven Geotextile (Polyester) when:

Creep Resistance is critical: Ideal for long-term reinforced slopes and retaining walls where the fabric acts as a structural element.

The project requires high tensile strength at very low elongation.

You are building on soft soils requiring immediate load-bearing support (e.g., embankments over peat).

5.Applications in Civil Engineering

Our high-strength woven geotextiles are widely used in:

Road & Railway Construction: Reinforcing the subgrade layer to prevent rutting and extend pavement life.

Basal Reinforcement: Supporting embankments over soft foundations (marshes, sludge ponds).

Retaining Structures: Functioning as the reinforcing element in Mechanically Stabilized Earth (MSE) walls and wrapped-face slopes.

Coastal Protection: Used in geotextile tubes and sandbags for erosion control and breakwaters.

Land Reclamation: Providing a stable separation layer for dredging and fill works.

6.Quality Assurance & Logistics

Direct Manufacturer: Produced in our ISO 9001 certified facility.

Third-Party Testing: SGS / TRI test reports available for each batch.

Packaging: Heavy-duty black PE film for UV protection during transport.

Export Capacity: Capable of shipping 50+ containers per month globally.

Ready to Reinforce Your Project?

Contact our engineering team for a technical consultation or a competitive price quote.

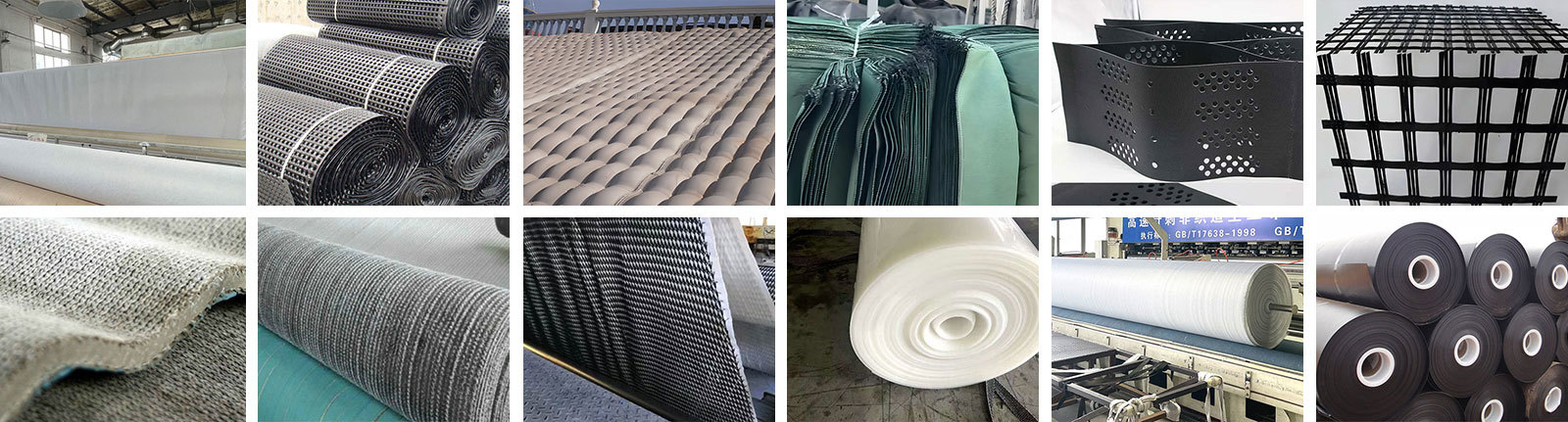

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE