How to Choose the Right HDPE Geomembrane for Landfill Liners?

Release time:

2026-01-07

Looking for the best containment solution? Discover why HDPE geomembranes are the top choice for landfill liners and how to select the right thickness and specifications for your project.

In the modern environmental protection industry, the integrity of containment systems is non-negotiable. Whether it is for municipal solid waste (MSW) or industrial hazardous waste, choosing the right HDPE (High-Density Polyethylene) geomembrane is the first line of defense against soil and groundwater contamination.

Why HDPE is the Gold Standard?

HDPE is preferred in the landfill industry due to its unique chemical and physical properties:

Chemical Resistance: It withstands a wide range of leachates and harsh chemicals.

UV Resistance: High-quality geomembranes are treated with carbon black to endure long-term exposure.

Durability: A properly installed HDPE liner can have a service life exceeding 50 years.

Key Factors to Consider During Procurement

Thickness Matters: For standard landfills, a thickness of 1.5mm to 2.0mm is typically required. Thicker liners offer better puncture resistance against sharp debris.

Smooth vs. Textured: On steep slopes, a textured geomembrane is essential to increase friction and prevent the sliding of overlapping layers or soil cover.

Standard Compliance: Ensure the material meets GRI-GM13 international standards, which specify the required density, tensile properties, and tear resistance.

Conclusion

Selecting a geomembrane is not just about the lowest price; it's about long-term environmental security. Always partner with a manufacturer that provides third-party testing reports and installation guidance.

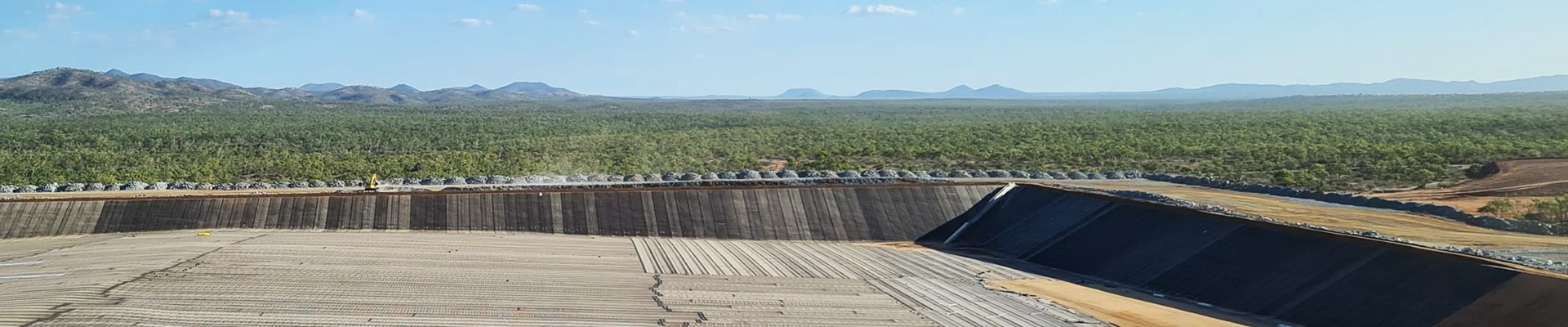

PROJECT CASES