Standard Certified By

1.5mm (60 mil) Smooth LDPE Geomembrane | Ultra-Flexible Liner for Tank & Tunnel Lining

Classification :

PRODUCT DETAILS

1. Product Overview

The Ultimate "Form-Fitting" Liner for Rigid Structures.

Lining a concrete tank, a tunnel, or a complex industrial sump requires a material that behaves differently than a standard landfill liner. Our 1.5mm (60 mil) Smooth LDPE Geomembrane offers the highest degree of flexibility and pliability in the polyethylene family.

Designed to act as a robust, independent bladder inside rigid structures, this 60 mil liner easily molds to sharp corners, sumps, and pipe penetrations without bridging or stressing. It is the premier solution for retrofitting leaking concrete tanks and waterproofing underground infrastructure where structural movement is expected.

2. Key Features

-

Maximum Conformability: LDPE is softer than both HDPE and LLDPE. It conforms tightly to the substrate surface, minimizing dead space and stress points, effectively acting like a second skin for your structure.

-

60 mil (1.5mm) Durability: While flexible, it is not flimsy. The 1.5mm thickness provides substantial physical strength and puncture resistance, suitable for long-term industrial containment and hydrostatic pressure.

-

High Elongation & Stress Relaxation: With elongation exceeding 800%, this liner absorbs expansion, contraction, and differential settlement of the host structure (e.g., cracked concrete) without rupturing.

-

Excellent Chemical Resistance: Provides a reliable barrier against water, wastewater, agricultural runoff, and many industrial chemicals (consult our chemical resistance chart for specifics).

-

Easy Detail Welding: The softer polymer structure makes detailed corner welding and pipe booting significantly easier and more secure than with rigid membranes.

3. Detailed Application Scenarios

Internal Lining of Concrete/Steel Tanks (Retrofitting)

Old concrete cisterns and steel tanks often develop cracks or corrosion. Sandblasting and recoating is temporary. Installing a 1.5mm Smooth LDPE Liner provides a permanent "tank-within-a-tank" solution. Its flexibility allows it to be pre-fabricated or installed on-site to fit rectangular or cylindrical shapes perfectly.

Tunnel & Basement Waterproofing

In tunneling (NATM or Cut-and-Cover), the waterproofing layer must withstand the rough shotcrete surface and ground shifting. 1.5mm LDPE is widely used as the waterproof membrane behind the final concrete lining due to its toughness and ability to stretch.

Industrial Sumps & Secondary Containment

For intricate containment areas with many pipes, plinths, and footings, rigid HDPE is a nightmare to install. Smooth LDPE can be cut and welded around these obstacles effortlessly, ensuring a leak-proof seal even in the tightest corners.

Root Barriers (Bamboo Control)

For aggressive bamboo or tree roots, a thick barrier is needed. 1.5mm provides a heavy-duty physical shield that directs roots downwards, protecting foundations and hardscapes.

4. Technical Specifications

| Property | Test Method | Unit | Typical Value (1.5mm LDPE) |

| Material | - | - | Virgin Low Density Polyethylene |

| Thickness | ASTM D5199 | mm (mil) | 1.50 mm (60 mil) |

| Density | ASTM D792 | g/cm³ | 0.910 - 0.929 |

| Tensile Strength (Break) | ASTM D6693 | N/mm | ≥ 24 |

| Elongation at Break | ASTM D6693 | % | ≥ 800% (Extreme Flexibility) |

| Tear Resistance | ASTM D1004 | N | ≥ 95 |

| Puncture Resistance | ASTM D4833 | N | ≥ 300 |

| Low Temp Brittleness | ASTM D746 | °C | < -75°C |

5. Installation Insight: Why 1.5mm LDPE is easier to install?

Installing liners in confined spaces (like inside a tank) is difficult.

-

Handling: 1.5mm LDPE rolls are less stiff than HDPE, making unrolling in tight spaces manageable.

-

Welding: It has a wider welding window and "flows" better during extrusion welding, creating safer, more reliable seams around complex details like pipe boots and corners.

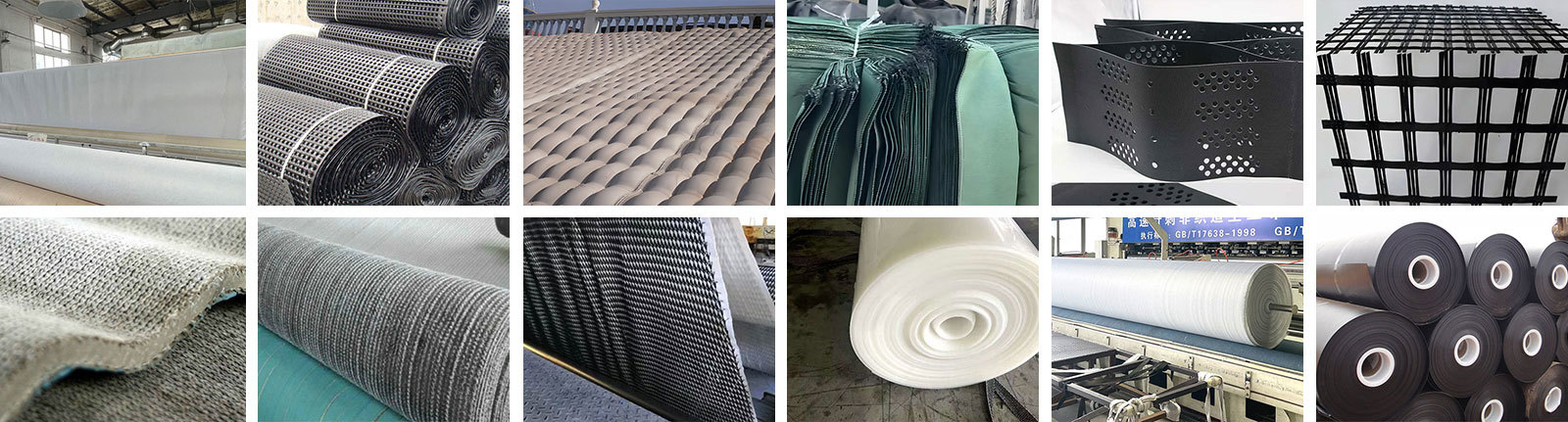

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE