Standard Certified By

Flexible LDPE & LLDPE Geomembrane Liner for High Elongation and Dynamic Applications

Classification :

PRODUCT DETAILS

1. Product Overview

The Ultimate Solution for Complex Geometries and Rough Subgrades.

Our LDPE Geomembrane Liner (Low Density Polyethylene) is engineered for projects where flexibility is paramount. Unlike rigid HDPE liners, our LDPE series offers exceptional elongation and conformability, allowing it to stretch and mold over irregular ground surfaces without stress cracking. It is the preferred choice for irrigation canals, agricultural ponds, and cold-region containment where ground settlement or freeze-thaw cycles are a concern.

2. Key Features

Superior Flexibility: Highly pliable material that easily conforms to corners, trenches, and uneven terrain.

High Elongation (>800%): Can withstand significant differential settlement of the subgrade without rupturing.

Cold Weather Performance: Remains flexible and non-brittle even in extreme low temperatures (-70°C), preventing thermal stress cracking.

Easy Installation: Softer material allows for faster deployment and easier welding, especially in tight spaces or detail work.

Non-Toxic: Safe for agricultural water storage and aquatic life (optional food-grade certification available).

3. Detailed Description

Why Choose LDPE Over HDPE?

While HDPE offers maximum chemical resistance, LDPE Geomembrane shines in physical adaptability. In projects with rough subgrades or potential for ground movement (subsidence), a rigid liner might crack. LDPE acts like a "tough skin" that stretches to accommodate these shifts. This makes it the ideal Canal Lining Material for retrofitting old, cracked concrete channels.

Engineered for Cold Climates

In regions like Northern Europe, Canada, or Russia, liners must endure harsh freeze-thaw cycles. Our LDPE liner maintains its integrity in freezing conditions where other plastics might shatter. It is widely used for winter water storage and ski resort reservoirs.

Applications Overview

Irrigation Canals: Lining earthen or cracked concrete ditches to prevent water loss.

Agricultural Ponds: Flexible liners for farm reservoirs and retention ponds.

Landfill Capping: Used as a final cover due to its ability to settle with the waste pile.

Temporary Containment: Rapid deployment for emergency spill control or remediation pads.

Root Barriers: Flexible protection for underground pipes and foundations.

4. Technical Specifications

| Property | Test Method | Unit | Typical Value (LDPE/LLDPE) |

|---|---|---|---|

| Material | - | - | Virgin Low Density Polyethylene |

| Thickness | ASTM D5199 | mm | 0.5mm - 2.5mm |

| Density | ASTM D792 | g/cm³ | 0.910 - 0.939 |

| Break Strength | ASTM D6693 | N/mm | ≥ 27 (for 1.0mm) |

| Elongation at Break | ASTM D6693 | % | ≥ 800% (High Flexibility) |

| Tear Resistance | ASTM D1004 | N | ≥ 100 |

| Low Temp Brittleness | ASTM D746 | °C | < -75°C |

For projects requiring extreme chemical resistance (e.g., hazardous waste), please view our HDPE Geomembrane.

5. Specifications and Compliance

Our LLDPE/LDPE products meet the highest standards for flexible polyolefin geomembranes:

- GRI-GM17 Standard: Product performance strictly adheres to the GRI-GM17 standard (Flexible Polyolefin Liner Specification) from the Geosynthetics Institute.

- Available Thicknesses: Available in a variety of thicknesses from 0.5mm to 2.5mm to meet diverse needs, from temporary covering to heavy-duty storage.

- Surface Finishes: Available in **smooth and textured** finishes; the textured finish is suitable for slopes requiring a high interfacial friction coefficient.

- Certification: NSF/ANSI 61 drinking water safety certification is available upon project request.

6. Explore By Thickness and Surface

Choose the specification that best suits your project's flexibility and strength requirements:

- [0.75mm Smooth LLDPE Liner] – Suitable for landscape lakes and temporary water storage; extremely flexible and easy to install.

- [1.0mm Textured LLDPE Liner] – Suitable for sewage treatment plant slopes, providing flexible impermeability and stable friction.

- [1.5mm Smooth LDPE Liner] – Suitable for concrete structure linings requiring maximum plasticity.

- [2.0mm Smooth LLDPE Liner] – Maximum thickness flexible lining for high-volume liquid storage.

FAQ

-

Q: What is the difference between LDPE and HDPE liners?

-

A: HDPE is stiffer and more chemically resistant, best for landfills. LDPE is more flexible and has higher elongation, making it best for uneven terrain, canals, and cold climates.

-

Q: Can LDPE liner withstand freezing temperatures?

-

A: Yes, our LDPE geomembrane has a brittleness temperature below -75°C, making it ideal for cold weather applications.

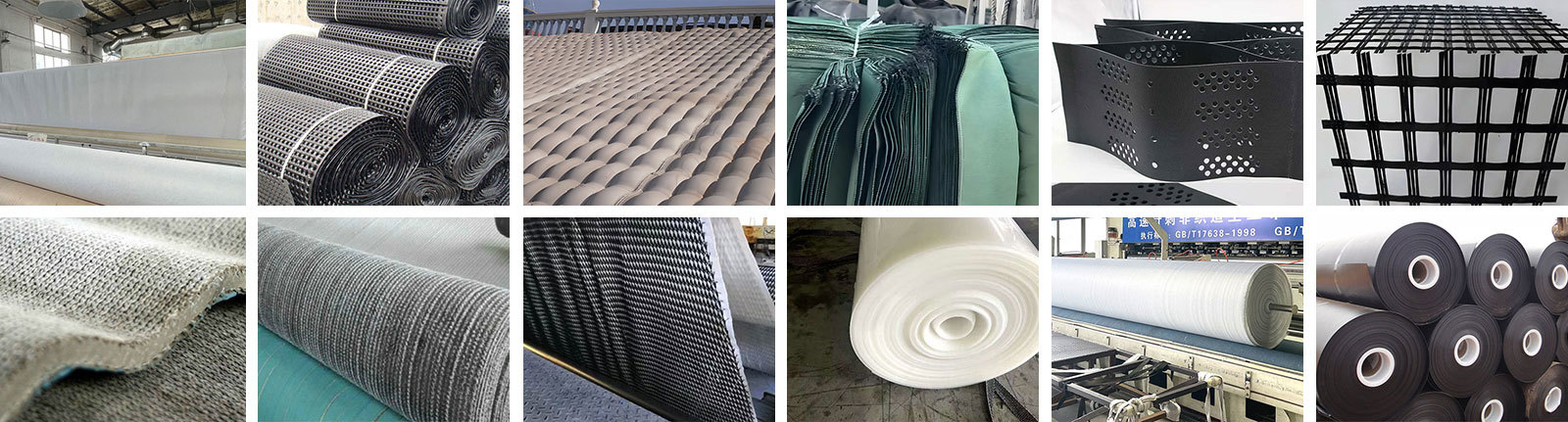

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE