Standard Certified By

1.0mm (40 mil) Textured LLDPE Geomembrane | High Friction Liner for Slope Stability & Capping

Classification :

PRODUCT DETAILS

1. Product Overview

Maximum Grip. Maximum Flexibility. The Ultimate Slope Solution.

Engineering a containment system on steep slopes or unstable ground requires more than just waterproofing. Our 1.0mm (40 mil) Textured LLDPE Geomembrane provides the perfect dual-solution. By combining the superior elongation of Linear Low-Density Polyethylene with a rough, high-friction surface, this liner prevents slope slippage while accommodating significant differential settlement. It is the industry standard for Landfill Capping (Closures) and environmentally sensitive embankments where ground movement is expected.

2. Key Features

-

High Friction Coefficient: The integrated textured surface (available Single or Double-Sided) drastically increases the interface friction angle, preventing the soil cover or geotextiles from sliding off steep slopes.

-

Settlement Resistant: Unlike rigid HDPE, our LLDPE liner offers exceptional multi-axial elongation. It stretches to bridge voids caused by waste decomposition or subgrade shifting without stress cracking.

-

Durable 40 mil Thickness: The 1.0mm profile offers excellent puncture resistance against root penetration and installation damage, suitable for long-term containment.

-

Cold Weather Flexibility: Maintains pliability and integrity in freezing conditions, making it easier to install on slopes in winter compared to stiff HDPE sheets.

-

Interface Stability: Specifically engineered to interlock with Geotextiles and GCLs (Geosynthetic Clay Liners), creating a stable, unified lining system.

3. Detailed Application Scenarios

Landfill Capping & Closures (Final Cover)

This is the #1 application for this product. As landfill waste decomposes, the pile settles unevenly. A rigid liner would crack, but our Textured LLDPE stretches to accommodate the subsidence. Simultaneously, the textured surface holds the topsoil and vegetation layer in place, preventing landslides on the cap.

Mining Heap Leach Pad Slopes

For side slopes in mining operations, you need a liner that won't let the valuable ore pile slide. The 1.0mm Textured LLDPE provides the necessary grip while enduring the harsh chemical environment (Note: For heap leach bottoms, HDPE is usually preferred; LLDPE is preferred for caps or areas needing high elongation).

Unstable Embankments & Levies

In civil engineering projects where the subgrade soil is soft or prone to shifting, Textured LLDPE ensures that the waterproofing layer remains intact even if the ground below moves, while keeping the protective cover soil stable.

4. Technical Specifications

| Property | Test Method | Unit | Typical Value (1.0mm Textured) |

| Material | - | - | Virgin LLDPE |

| Thickness (Nominal) | ASTM D5994 | mm (mil) | 1.0 mm (40 mil) |

| Asperity Height (Texture) | ASTM D7466 | mm | ≥ 0.25 mm (Crucial for Grip) |

| Break Strength | ASTM D6693 | N/mm | ≥ 15 |

| Elongation at Break | ASTM D6693 | % | ≥ 800% (High Flexibility) |

| Tear Resistance | ASTM D1004 | N | ≥ 100 |

| Puncture Resistance | ASTM D4833 | N | ≥ 250 |

5. Why "Textured LLDPE" and not "Textured HDPE"?

-

Select Textured LLDPE (This Product) when: You expect settlement (like on a landfill cap), the subgrade is soft/uneven, or you need easier installation on slopes in cold weather.

-

Select Textured HDPE when: The ground is perfectly stable/compacted (like a new landfill bottom cell) and maximum chemical resistance is the absolute priority.

Complete your Landfill Cap System with our Drainage Geocomposite.

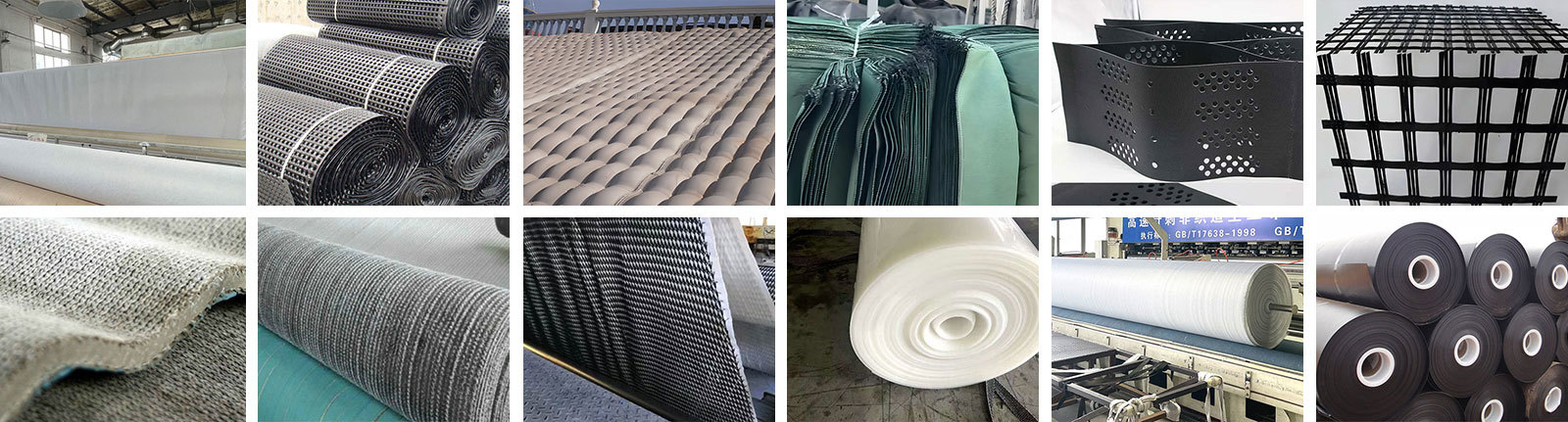

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE