Standard Certified By

2.0mm (80 mil) Smooth LLDPE Geomembrane | Heavy-Duty Flexible Liner for Mining & Reservoirs

Classification :

PRODUCT DETAILS

1. Product Overview

Extreme Durability Meets Ultimate Flexibility.

For projects that demand the physical toughness of a thick liner but cannot risk the stress cracking associated with rigid HDPE, our 2.0mm (80 mil) Smooth LLDPE Geomembrane is the singular solution.

This heavy-duty liner offers the same thickness and puncture resistance as standard mining liners but features a unique Linear Low-Density Polyethylene molecular structure. This allows it to absorb significant differential settlement and ground movement without rupturing, making it the safest choice for large-scale reservoirs, landfill caps, and mining containment on unstable subgrades.

2. Key Features

-

80 mil (2.0mm) Armor: The substantial thickness provides exceptional puncture resistance against sharp rocks and construction loads, reducing the need for expensive sand bedding compared to thinner liners.

-

Settlement Proof: With an elongation at break exceeding 800%, this liner acts like a tough elastic skin. It stretches to bridge voids caused by sinkholes or subsiding waste piles where rigid liners would fail.

-

Arctic Grade Flexibility: Engineered to remain pliable in extreme cold. It resists thermal contraction stress, making it ideal for projects in Canada, Russia, and high-altitude regions.

-

Easy Welding: The 2.0mm thickness provides ample material for a robust double-track hot wedge weld, ensuring high weld strength and easy air channel testing.

-

Chemical Resistance: While flexible, it maintains excellent resistance to brine, saltwater, and general industrial wastewater.

3. Detailed Application Scenarios

Large Earthen Reservoirs & Dams

In massive water storage projects, the sheer weight of the water can cause the ground to settle over time. A 2.0mm Smooth LLDPE Liner provides the structural integrity to hold millions of gallons of water while accommodating these geological shifts, preventing catastrophic leakage.

Mining & Oil Field Frack Ponds

For "Frack Ponds" or produced water pits in the oil and gas industry, liners are often exposed to rough handling and heavy equipment. The 80 mil thickness withstands mechanical abuse, while the LLDPE material prevents environmental stress cracking (ESCR) typical in exposed conditions.

Landfill Caps (Final Cover)

The top of a landfill is constantly moving as waste decomposes. A 2.0mm LLDPE liner is heavy enough to sit flat without wind uplift issues (ballast effect) and flexible enough to settle with the trash mountain for decades.

Remediation Pads

For temporary soil treatment pads where heavy trucks dump contaminated soil, the 2.0mm thickness is essential to prevent tires from shredding the liner, while the flexibility ensures it conforms to the berms and drainage sumps.

4. Technical Specifications

| Property | Test Method | Unit | Typical Value (2.0mm LLDPE) |

| Material | - | - | Virgin LLDPE |

| Thickness | ASTM D5199 | mm (mil) | 2.00 mm (80 mil) |

| Density | ASTM D792 | g/cm³ | 0.915 - 0.939 |

| Tensile Strength (Break) | ASTM D6693 | N/mm | ≥ 53 (High Strength) |

| Elongation at Break | ASTM D6693 | % | ≥ 800% |

| Tear Resistance | ASTM D1004 | N | ≥ 150 |

| Puncture Resistance | ASTM D4833 | N | ≥ 480 (Heavy Duty) |

| Carbon Black Content | ASTM D1603 | % | 2.0 - 3.0 |

5. 2.0mm Comparison: LLDPE vs. HDPE

-

Q: When should I choose 2.0mm LLDPE over 2.0mm HDPE?

-

A: Choose 2.0mm LLDPE if your site has soft soil, potential for ground settlement, or requires a liner that is easy to fold and pre-fabricate.

-

A: Choose 2.0mm HDPE only if the ground is perfectly compacted (like concrete) and your primary concern is extreme chemical resistance (e.g., strong acids in hazardous waste).

-

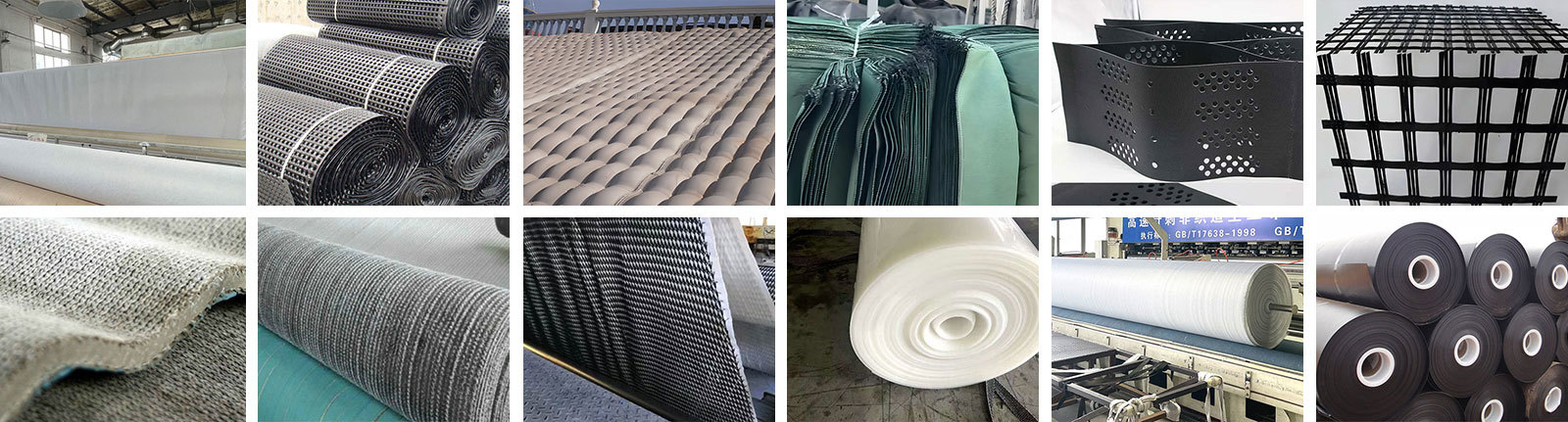

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE