What are the characteristics of waterproof board

Release time:

2025-09-23

The waterproof board HDPE waterproof board (new HDPE waterproof board) used for underground anti-corrosion and anti-seepage projects adopts three-layer co-extrusion technology, adopts the world's advanced automatic geotextile production equipment and low-pressure high-density polyethylene raw materials, carbon black, anti-aging Agents, antioxidants, UV absorbers, stabilizers and other auxiliary materials compounded by formula on the basis of ordinary waterproof boards. This production line is highly automated. From order entry, formula, feeding, processing to quality monitoring, fully automatic computer control, strictly in accordance with scientific data operation. It can also use advanced raw materials (with super tensile strength), such as Metallocenence and traditional PE, EVA, LLDPE, etc.

The waterproof board HDPE waterproof board (new HDPE waterproof board) used for underground anti-corrosion and anti-seepage projects adopts three-layer co-extrusion technology, adopts the world's advanced automatic geotextile production equipment and low-pressure high-density polyethylene raw materials, carbon black, anti-aging Agents, antioxidants, UV absorbers, stabilizers and other auxiliary materials compounded by formula on the basis of ordinary waterproof boards. This production line is highly automated. From order entry, formula, feeding, processing to quality monitoring, fully automatic computer control, strictly in accordance with scientific data operation. It can also use advanced raw materials (with super tensile strength), such as Metallocenence and traditional PE, EVA, LLDPE, etc.

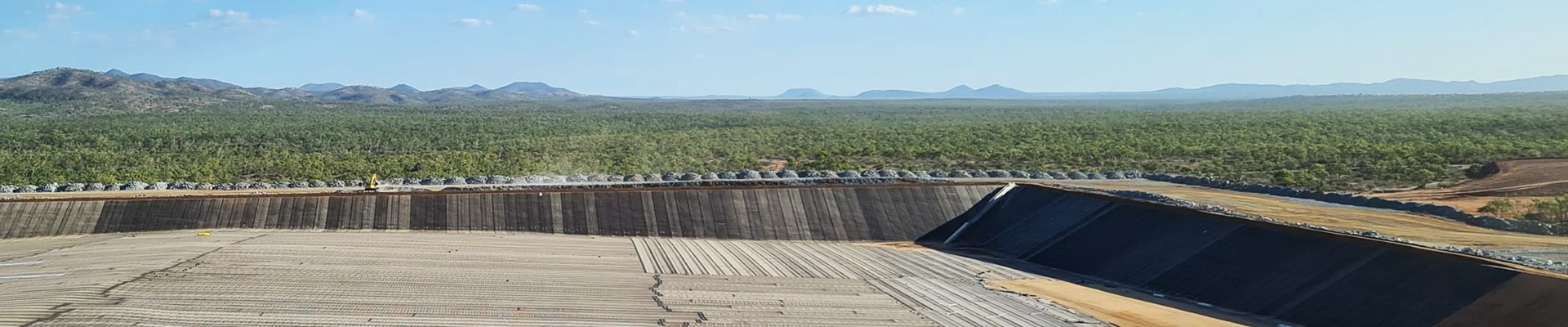

The waterproof board is 4-6m wide and weighs 200-1500g/m2. It has high physical and mechanical performance indicators, such as tensile strength, tear resistance and burst resistance. The product has the characteristics of high strength, good elongation, large deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance and good impermeability. It can meet the needs of civil engineering projects such as anti-seepage, isolation, reinforcement, crack prevention and reinforcement in water conservancy, municipal administration, construction, transportation, subway, tunnel and engineering construction. Due to the selection of polymer materials and anti-aging agents added during production, it can be used in unconventional temperature environments. This flashing is commonly used for anti-seepage treatment of dams, drains and dumps.

Now is the peak season for flashing production, and it is also the season for waterproofing reinforcement. Due to the change of weather, it is beneficial to the construction of waterproof board to a certain extent. The emergence of this phenomenon has increased the price of waterproofing boards. Although the price of the waterproof board has increased, the HDPE particles of the raw material of the waterproof board will also rise accordingly, but the particles of the waterproof board are also kept pure in quality and color to ensure the waterproof board produced. Therefore, it is necessary to dig an intercepting ditch at the perimeter boundary and embed the waterproofing board in the ditch. The quality inspection of the flashing will be carried out according to the different progress of the construction environment. In this way, the ex-factory price of the waterproof board will be reduced on average.

PROJECT CASES