Composite geomembrane: the "hidden champion" in the field of global infrastructure anti-seepage

Release time:

2025-10-24

Composite geomembranes are widely used in global water conservancy, environmental protection, mining and other fields due to their innovative structure, excellent performance and cost advantages. Foreign trade procurement should pay attention to technical parameters, supplier strength and logistics solutions, and follow the green and intelligent trend to seize market opportunities.

Amidst the global surge in infrastructure construction, a seemingly unassuming yet crucial material is quietly changing the game: geomembrane. From Southeast Asia's water conservancy hubs to the desert oil fields of the Middle East, from South American landfills to tunnel projects in Northern Europe, this composite material, made of a polymer membrane and geotextile, has become a global engineering imperative thanks to its dual properties of waterproofing and reinforcement. This article will provide an in-depth analysis of geomembrane's technical advantages, application scenarios, and a guide to foreign trade procurement, helping you accurately access the international market.

I. Technical Analysis: Why is geomembrane so popular in global projects?

1. Structural Innovation: A 1+1+2 Anti-seepage System

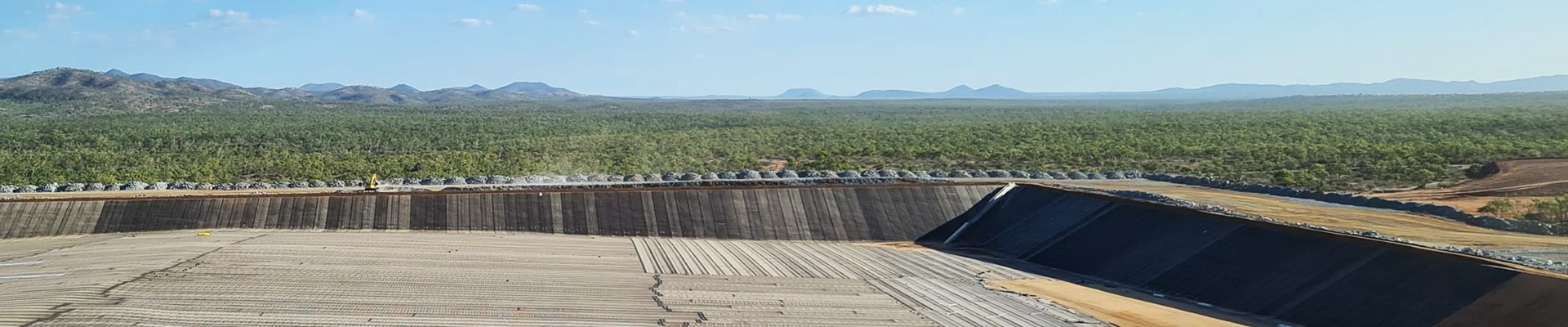

Geomembrane utilizes a "geomembrane + geotextile" composite structure, with the geomembrane (such as HDPE, LDPE, or EVA) providing the core anti-seepage function, while the geotextile (staple fiber needle-punched fabric or filament spunbond fabric) provides protection, drainage, and reinforcement. For example, in a reservoir project in Indonesia, a two-fabric-one-membrane structure successfully withstood groundwater pressure. The geotextile layer effectively dispersed the impact of rocks, extending the membrane's service life.

2. Performance Breakthrough: An "All-Around Warrior" for Extreme Environments

Weather Resistance: HDPE membranes with added anti-aging agents can operate stably in environments ranging from -50°C to 80°C. A Middle Eastern oil field project has demonstrated UV resistance for over 10 years.

Mechanical Strength: With a tensile strength exceeding 25kN/m and a bursting strength exceeding 3kN, they can withstand soil settlement and compaction by construction machinery.

Environmental Protection: EU REACH certified, no heavy metal release, and in compliance with global environmental standards.

3. Cost Advantage: 30% lower total cost than traditional solutions

Compared to concrete cut-off walls, composite geomembranes are 50% faster to install, with 40% lower material costs and no curing period. Data from an irrigation project in Vietnam showed that the use of composite geomembranes shortened the project schedule by six months, resulting in a 28% overall cost reduction.

II. Global Application Map: Comprehensive Coverage from Water Conservancy Projects to Environmental Protection

1. Water Conservancy Projects: The "Core Line of Defense" for Seepage Control and Reinforcement

Dembankment Reinforcement: In the Ganges River flood control project in Bangladesh, 6m wide composite geomembranes were seamlessly welded, protecting against monsoon flooding.

Channel Seepage Control: The Nile River irrigation channel in Egypt uses a 0.5mm thick HDPE membrane, reducing seepage by 90% and increasing water resource utilization by 35%.

2. Environmental Protection Projects: The "Last Barrier" for Pollution Control

Landfills: A landfill in Saudi Arabia uses a composite geomembrane as its lining and has experienced zero leachate leakage in 10 years, certified by an international environmental organization.

Wastewater Treatment: The São Paulo wastewater treatment plant in Brazil uses EVA composite membrane, which offers excellent chemical resistance and reduces operating costs by 20%.

3. Mining and Transportation: Customized Solutions for Special Scenarios

Tailings Ponds: A Chilean copper mine tailings pond uses an acid- and alkali-resistant composite membrane, boasting a service life of 15 years, far exceeding that of traditional materials. Tunnel Engineering: The Norwegian underwater tunnel uses a double-membrane, single-fabric structure, achieving a waterproof rating of P12 and meeting 120-meter head pressure requirements.

III. Foreign Trade Procurement Guide: How to Choose a Reliable Supplier?

1. Core Parameters: Understanding the Technical Specifications

Membrane Material Types: HDPE (general-purpose), LDPE (flexible), EVA (suitable for low temperatures).

Physical Specifications: Thickness (0.2-3.0mm), Breaking Strength (≥17kN/m), CBR Bursting Strength (≥2.5kN).

Environmental Certifications: EU CE Certification, ISO9001 Quality Management System, SGS Test Report.

2. Supplier Screening: Avoid "Low Price Traps"

Production Capacity: Prioritize factories with widths of 6 meters or more and daily production capacity exceeding 100,000 square meters to ensure stable supply for large projects.

References: Requires at least three international project references, such as hydropower stations in Southeast Asia and oil fields in the Middle East.

Service Support: Confirm whether welding equipment, construction guidance, and a quality warranty (usually 2-5 years) are provided. 3. Logistics Solutions: Optimizing Cross-Border Transportation Costs

Container Consolidation: A 20-foot container can carry approximately 20,000 square meters of geomembrane, reducing ocean freight costs by $0.30 per square meter after amortization.

Customs Clearance Documents: Ensure the complete certificate of origin, MSDS report, and quality inspection certificate are complete to avoid delays at the destination port.

IV. Future Trends: The Integration of Green Infrastructure and Intelligence

As global carbon neutrality targets progress, geomembranes are evolving in the following directions:

Degradable Materials: Developing PLA (polylactic acid)-based composite membranes to achieve natural decomposition at the end of their lifecycle.

Intelligent Monitoring: Embedded sensors provide real-time feedback on pressure and temperature data within the anti-seepage layer, providing early warning of potential leakage risks.

3D Printing Technology: Customizable membrane materials for custom-shaped structures to accommodate complex terrain construction requirements.

Conclusion: Seizing the "Golden Entrance" to the Global Infrastructure Market

Geomembrane is no longer just an anti-seepage material; it also symbolizes engineering efficiency and sustainability. For foreign trade companies, understanding the technological trends and procurement needs of this market segment will help you gain an advantage in emerging markets such as Southeast Asia, the Middle East, and Latin America. Contact professional suppliers now to obtain customized solutions and make your products the "hidden champions" of global infrastructure projects!

PROJECT CASES