Bentonite waterproof blankets – a green barrier for global infrastructure and environmental projects

Release time:

2025-10-31

Bentonite waterproofing blankets (GCLs), as a core seepage prevention material for green infrastructure, are widely used in municipal infrastructure, environmental protection projects, water conservancy projects and other fields due to their superior seepage prevention performance, environmental sustainability and convenient construction, thus contributing to the global sustainable development goals.

What is a Bentonite Waterproof Blanket?

A bentonite waterproof blanket (Geosynthetic Clay Liner, GCL) is a flexible waterproof material composed of natural sodium-based bentonite granules and polypropylene woven/non-woven fabric. Its core principle lies in the fact that bentonite swells upon contact with water to form a gel-like clay layer, achieving seamless seepage prevention through its "self-healing" properties. It is widely used in global infrastructure and environmental engineering projects.

Key Advantages: Why Choose a Bentonite Waterproof Blanket?

Superior Seepage Prevention Performance

• Bentonite granules swell 15-20 times upon contact with water, forming a dense clay layer with a permeability coefficient ≤5×10⁻¹¹m/s, far exceeding traditional seepage prevention materials.

• High puncture resistance, able to withstand damage from tree roots, rocks, and other external forces, suitable for complex geological environments.

Environmentally Friendly and Sustainable

• Abundant natural bentonite resources; low-carbon emissions during production, complying with EU REACH, US ASTM D5891, and other environmental standards.

• Recyclable and reusable; construction waste can be reprocessed, reducing construction debris.

Convenient and Economical Construction

• Each roll weighs only 500-1000kg, making manual installation 3-5 times more efficient than traditional clay layers, significantly reducing labor costs.

• No specialized equipment required; adaptable to various terrains, shortening construction time by over 30%.

Global Application Scenarios and Cases

Municipal Infrastructure: Bentonite waterproofing blankets were used in the Beijing Daxing Airport underground utility tunnel and Dubai Metro tunnel seepage prevention projects, effectively resisting groundwater erosion.

Environmental Engineering: GCL was used as a composite seepage prevention layer in the Hamburg landfill in Germany and the Sydney sewage treatment plant in Australia, meeting the EU Landfill Directive seepage prevention standards.

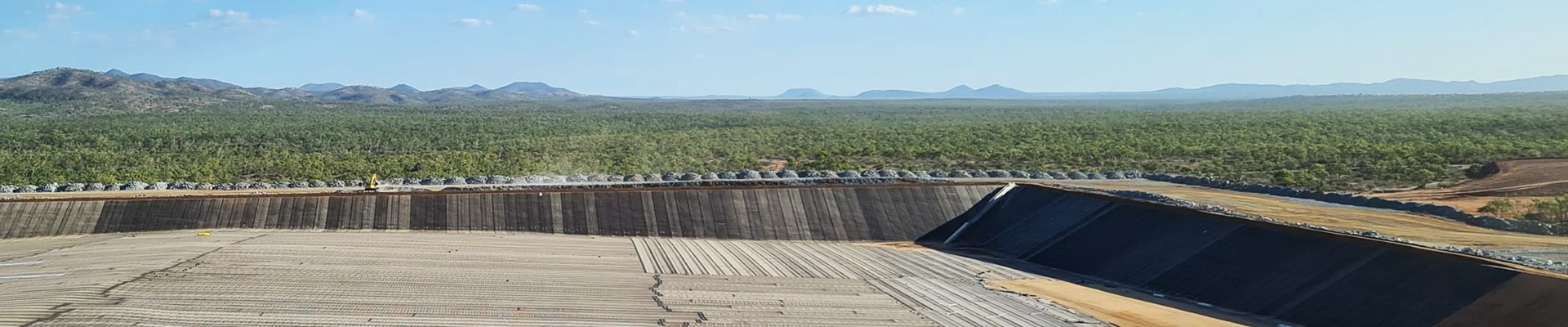

Water Conservancy Projects: Bentonite waterproofing blankets were used for riverbank protection and reservoir seepage prevention in the Itaipu Hydropower Station in Brazil and the Nile River Dam project, demonstrating excellent freeze-thaw resistance.

Agriculture and Landscape: Moisture-proofing of greenhouse foundations in the Netherlands and seepage prevention projects for artificial lakes at golf courses in California, USA, showcasing its aging resistance and chemical corrosion resistance.

Technical Parameters and Certification Standards

Physical Properties: Tensile strength ≥600N/5cm, elongation 15%-20%, adaptable to foundation deformation requirements.

Environmental Certification: Certified by ISO 9001 Quality Management System and ISO 14001 Environmental Management System; some products have obtained NSF international drinking water safety certification.

Customized Production: Can be supplemented with UV stabilizers and anti-aging agents, suitable for special environments such as saline-alkali land and high-altitude cold regions; thickness specifications adjustable from 5mm to 10mm.

Market Trends and Foreign Trade Opportunities

With the advancement of global "dual carbon" goals, the demand for bentonite waterproofing blankets is surging in the fields of green infrastructure, sponge cities, and ecological restoration. Southeast Asian countries such as Vietnam and Indonesia are building large-scale waste incineration power plants, urgently needing high-performance seepage prevention materials; desertification control projects in the Middle East and water resource management projects in Africa are also emerging markets. As the world's largest bentonite producer, China, leveraging its complete industrial chain and cost advantages, is exporting high-end GCL products and construction solutions through the "Belt and Road" initiative.

Conclusion

Bentonite waterproofing blankets, as a core material for green infrastructure, are becoming the preferred solution in the global engineering field due to their superior impermeability, environmental friendliness, and economic value. Through technological innovation and customized production, Chinese suppliers can further expand into international markets and contribute to global sustainable development goals. For more technical details or project quotations, please contact our foreign trade team for customized solutions!

PROJECT CASES