HDPE geomembrane: A core solution for global environmental protection and engineering seepage prevention.

Release time:

2025-11-03

HDPE geomembrane, with its excellent seepage prevention performance, durability and environmental protection characteristics, has become the core material for seepage prevention solutions in many fields such as environmental protection engineering, water conservancy engineering, mining and agriculture. Market demand continues to expand with the strengthening of environmental protection policies and the growth of infrastructure investment.

I. Technical Characteristics: A Revolution in Seepage Control with High-Density Polyethylene

HDPE geomembrane uses high-density polyethylene (HDPE) resin as its core raw material, with a density ≥0.94g/cm³. Through the addition of anti-aging agents, carbon black, and special plastic additives, a dense molecular structure is formed. Its seepage control coefficient reaches 1×10⁻¹⁷ cm/s, far exceeding traditional seepage control materials, effectively blocking liquid and gas penetration. The material exhibits outstanding chemical corrosion resistance, resisting strong acids, alkalis, oils, and over 80 kinds of chemical media, with a service life of over 50 years. In terms of environmental adaptability, HDPE geomembrane can operate stably in extreme temperatures ranging from -70℃ to 110℃, with a tensile strength of up to 28MPa and an elongation at break of 700%, adapting to complex stress environments such as geological subsidence and earthquakes. Furthermore, its smooth/roughened surface design enhances friction with the foundation, and the composite structure (one layer of fabric and one layer of membrane/two layers of fabric and one layer of membrane) further improves engineering stability.

II. Application Scenarios: Covering All Fields from Landfill to Marine Engineering

HDPE geomembranes are used across multiple fields including environmental protection, water conservancy, municipal engineering, and mining:

Environmental Engineering: In landfills, they serve as a bottom impermeable layer and a top capping layer to prevent leachate from contaminating groundwater; in wastewater treatment plants, they are used for seepage prevention in biological treatment ponds and sedimentation tanks.

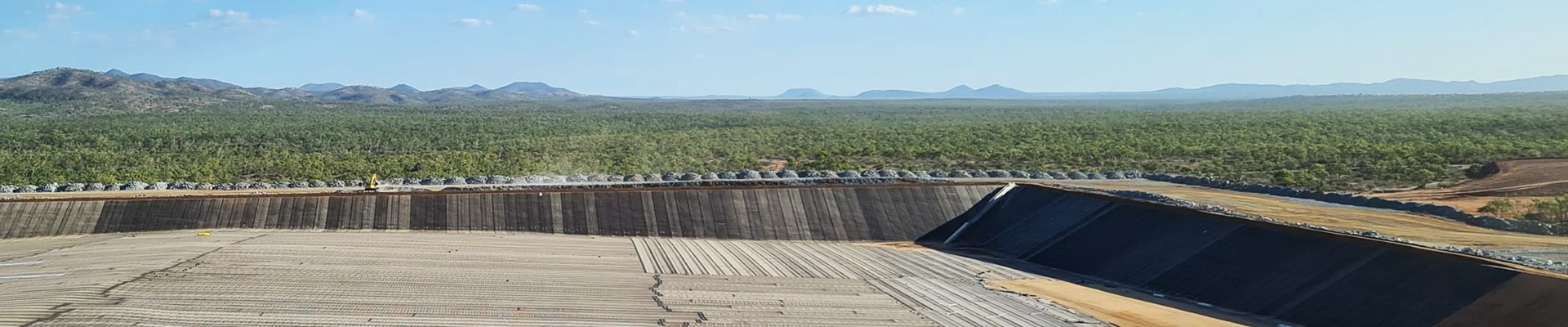

Water Conservancy Engineering: Reinforcement and seepage prevention in reservoirs, dams, and canals, effectively reducing water loss; in artificial lakes and riverbank protection projects, they maintain the ecological balance of water bodies.

Municipal and Transportation: Waterproofing of subway tunnels and basements; roadbed reinforcement to prevent rainwater infiltration from causing structural damage.

Industry and Mining: Seepage prevention and isolation in chemical plant tank areas and tailings ponds; oil spill prevention in oilfield extraction; salt film covering for salt crystallization ponds.

Agriculture and Ecology: Seepage prevention in irrigation systems and aquaculture ponds; water retention in saline-alkali land reclamation; vegetation layer protection in ecological restoration projects.

III. Production Process: Precision Technology and Quality Control

HDPE geomembrane production employs blown film or calendering processes. The process includes raw material mixing, melt plasticizing, extrusion molding, cooling and shaping, thickness testing, and packaging. The core raw material is high-density polyethylene resin, supplemented with additives such as anti-aging agents, carbon black, and color masterbatch. After uniform mixing in an electric mixer, it is melt plasticized in an extruder, extruded into molten tube blanks through an annular die, and then blown into shape, cooled, drawn, and wound for packaging. The production process strictly adheres to the GB/T17643-2011 standard, with thickness specifications ranging from 0.25mm to 3.0mm, supporting customized smooth, textured, and composite structures. Quality testing covers physical properties such as thickness, tensile strength, and permeability coefficient to ensure that the product meets international environmental and engineering standards.

IV. Market Trends: Global Demand Growth and Technological Innovation

According to QYResearch data, the global HDPE geomembrane market reached several billion US dollars in 2023 and is projected to continue growing at a compound annual growth rate (CAGR) until 2030. China, as the largest producer and consumer, accounts for over 30% of the market. Market drivers include: increasingly stringent global environmental policies leading to a surge in demand for landfill and wastewater treatment plant construction; infrastructure upgrades resulting in increased investment in water conservancy and transportation projects; and higher performance requirements for geomembranes in the mining and agricultural sectors. In terms of technological trends, the industry focuses on improving the material's resistance to UV aging and stress cracking, and exploring bio-based HDPE raw materials to promote green production. In the competitive landscape, leading companies consolidate their market position through technological innovation and capacity expansion, while emerging companies enter niche markets through differentiated products.

Conclusion

HDPE geomembranes, with their superior impermeability, durability, and environmental friendliness, have become an irreplaceable core material in the global engineering seepage control field. With strengthened environmental policies, increased infrastructure investment, and continuous technological innovation, market demand will continue to expand. Foreign trade enterprises should focus on product differentiation, quality certification, and alignment with international standards, seize the opportunities presented by infrastructure construction in countries along the Belt and Road Initiative, and promote the widespread application and value enhancement of HDPE geomembranes in the global market.

PROJECT CASES