HDPE vs. LDPE geomembrane: Choosing the right liner for your project

Release time:

2025-11-05

This article provides a detailed comparison of the performance and applications of HDPE geomembrane (high rigidity, chemical resistance, and UV resistance, suitable for landfills and mining) and LDPE geomembrane (good flexibility, easy installation, and settlement adaptability, suitable for ponds and complex terrain) to help international buyers make the right selection based on project requirements.

Introduction - Setting the Scene and Establishing Expertise

In today's civil engineering and environmental protection fields, geomembranes are crucial materials for ensuring the safe containment of liquids and waste. However, among the many options, HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are the two most frequently discussed.

Although both belong to the polyethylene family, fundamental differences in their molecular structure and physical properties determine their performance in different applications. As a professional global supplier of geosynthetics, we are frequently asked, "Should I choose HDPE or LDPE?"

This article will provide an in-depth comparison of these two materials to help you make the most informed and cost-effective choice for your specific project, whether it's a landfill, mining, or aquaculture.

1. Core Material Definition

①HDPE Geomembrane (High-Density Polyethylene Geomembrane)

HDPE geomembranes are made from high-density polyethylene resin. Their tightly packed molecular chains give them:

High rigidity and high tensile strength.

Excellent chemical resistance, especially against acids, alkalis, and corrosive liquids.

Excellent UV resistance makes it ideal for exposed applications such as landfill mulch.

②LDPE Geomembrane (Low-Density Polyethylene Geomembrane)

In contrast to HDPE, LDPE geomembrane is made from low-density polyethylene resin. Its looser molecular chain structure gives it:

Excellent flexibility and high elongation.

Easy to install, especially in applications requiring conformation to irregular shapes or complex terrain.

Good low-temperature performance.

2. HDPE vs. LDPE: Head-to-Head Comparison

To help you make a quick decision, here is a direct comparison of the two materials in key performance aspects:

Flexibility and Elongation

LDPE (Winner): This is LDPE's biggest advantage. It is very flexible and can easily conform to ground contours, corners, and pipes. Its high elongation makes it less prone to breakage when facing uneven foundation settlement.

HDPE: Relatively rigid. While this provides structural strength, it requires more cutting and welding when installed in complex terrain and is less adaptable to foundation settlement.

Chemical Resistance

HDPE (Winner): HDPE's compact molecular structure makes it the industry benchmark for resistance to chemicals and industrial wastewater. It is the material of choice for landfills and mining heap leaching ponds because it can resist corrosive substances for extended periods.

LDPE: Has good chemical resistance, but not as widespread as HDPE. It is sufficient for non-corrosive liquids such as aquaculture or ornamental ponds.

UV Resistance and Weather Resistance

HDPE (Winner): HDPE (especially black geomembranes containing sufficient carbon black) has excellent UV resistance and can be exposed to sunlight for extended periods without degradation.

LDPE: Relatively more susceptible to UV degradation; it is generally recommended to cover it as soon as possible after installation (e.g., using soil or water).

Strength and Puncture Resistance

HDPE: Due to its high density, HDPE has higher puncture resistance and tensile strength. It is more "tough" and can resist mechanical damage during installation.

LDPE: Relatively soft and more easily punctured by sharp objects.

3. LLDPE Geomembrane: The Important "Balanced Option"

When discussing HDPE and LDPE, LLDPE (linear low-density polyethylene) must be mentioned. LLDPE falls between the two in terms of performance:

It is stronger and more puncture-resistant than LDPE.

It is more flexible and has better elongation than HDPE.

For many projects that require a balance between strength and flexibility (such as secondary containment or cover systems), LLDPE is becoming a very attractive option.

4. Selection Guide: Which Geomembrane is Right for Your Project?

Choosing the right material directly affects the safety and lifespan of the project.

✅ Preferred HDPE Geomembrane (Choose HDPE Geomembrane If...)

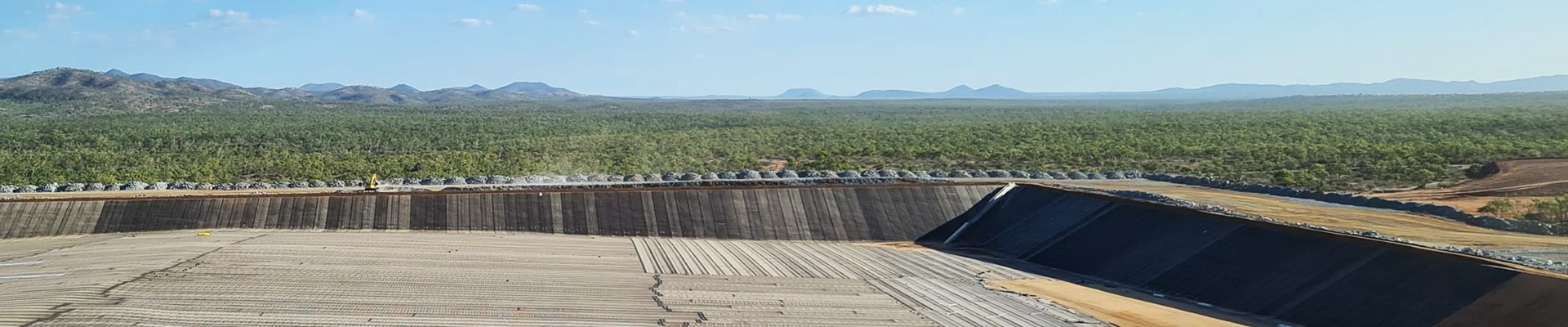

Project Types: Landfills, Mining (Heap Leaching Ponds, Tailings Dams), Large Reservoirs, Wastewater Treatment Plants.

Key Requirements: Must possess top-tier chemical resistance, extremely high UV resistance (for exposed applications), and maximum mechanical strength and puncture resistance.

✅ Preferred LDPE/LLDPE Geomembrane (Choose LDPE/LLDPE Geomembrane If...)

Project Types: Aquaculture Ponds, Decorative Ponds, Golf Course Water Features, Tunnel Seepage Prevention, Foundation Moisture Protection.

Key Requirements: Extreme flexibility (requiring conformability to complex shapes), ease of on-site prefabrication and installation, and the ability to accommodate potential foundation settlement.

Conclusion

There is no absolute "better" choice between HDPE and LDPE, only "more suitable". HDPE is a robust and durable chemical barrier, while LDPE (and LLDPE) are flexible and easy-to-install containment experts.

As a geomembrane manufacturer with extensive export experience, we understand the diverse needs of projects worldwide. We not only offer high-quality products that meet international standards of GRI-GM13 (HDPE) and GRI-GM17 (LLDPE), but also provide professional technical support.

Unsure which material is best for your project?

Contact us today for a free expert consultation, detailed technical data sheets, and a competitive international quote. Let our experts help you choose the most reliable and cost-effective liner solution for your project.

PROJECT CASES