A Deep Dive into HDPE Geomembranes: Types, Properties, and Key Applications

Release time:

2025-11-07

Explore the complete guide to HDPE Geomembranes (HDPE Liners). Understand the unique properties of Smooth, Textured, and Composite HDPE types, their manufacturing standards, and critical anti-seepage applications in landfills, aquaculture, and hydraulic projects. Get your high-quality HDPE solutions now!

Introduction: The Cornerstone of Global Anti-Seepage Solutions

In the demanding field of high-standard containment engineering, the HDPE Geomembrane (High-Density Polyethylene Liner) has long maintained a central position due to its exceptional performance and cost-effectiveness. The HDPE material offers outstanding chemical resistance, UV stability, and extremely low permeability, making it the ideal barrier to protect the environment and infrastructure from leakage and contamination.

For global infrastructure, environmental, and energy projects, selecting the correct HDPE Geomembrane Type is crucial for ensuring the long-term success and integrity of the project.

I. Main Types and Characteristics of HDPE Geomembranes

HDPE Geomembrane is not a single product; it is categorized into several main types based on surface treatment and structure, each designed to meet specific engineering requirements.

1. Smooth HDPE Geomembrane

Characteristic | Description | Applicable Scenarios |

|---|---|---|

Surface | Completely smooth, non-textured. | Landfill bottom liners, reservoir containment, foundation damp-proofing. |

Advantages | Cost-effective, lowest permeability, high welding efficiency, easy to clean. | |

Limitations | Requires specific anchoring design on steep slopes to prevent sliding. |

2. Textured HDPE Geomembrane

Characteristic | Description | Applicable Scenarios |

|---|---|---|

Surface | One or both sides feature raised textures or indentations. | Steep slope containment (e.g., dams, tailings facilities). |

Advantages | High friction coefficient, provides excellent shear strength and interface friction, effectively preventing the sliding of soil cover layers or overlaid materials. | |

Limitations | Production cost is slightly higher than smooth type. |

3. Composite HDPE Geomembrane

Characteristic | Description | Applicable Scenarios |

|---|---|---|

Structure | HDPE Geomembrane thermally laminated with a Geotextile layer. | Areas requiring both anti-seepage and protection/filtration functions. |

Advantages | The Geotextile layer offers cushioning protection against punctures from sharp objects and assists with drainage. | |

Limitations | Installation is more complex than standalone HDPE membrane, requiring specialized equipment. |

II. Key Technical Advantages of HDPE Liners

High-quality HDPE Geomembranes deliver performance unmatched by many other materials:

Exceptional Impermeability: Extremely low permeability coefficient (typically below $1.0 \times 10^{-13} \text{ cm/s}$), ensuring virtually zero leakage.

Chemical Resistance: Highly resistant to acids, alkalis, salts, and many organic solvents, suitable for industrial waste and chemical fluid storage.

UV Resistance and Longevity: Stabilized with Carbon Black, providing excellent resistance to UV degradation, suitable for long-term outdoor exposure.

High Mechanical Strength: Possesses superior tensile strength, puncture resistance, and tear resistance.

III. Core Application Fields of HDPE Geomembranes

As a versatile anti-seepage barrier, the HDPE Geomembrane is widely applied across the following critical sectors:

1. Environmental Engineering

Landfill Liners: Used as the base and cap anti-seepage layer to prevent pollutants (leachate) from infiltrating groundwater and soil.

Hazardous Waste Containment: Used for the containment and isolation of hazardous waste storage facilities, ensuring chemical safety.

2. Hydraulic and Aquaculture Projects

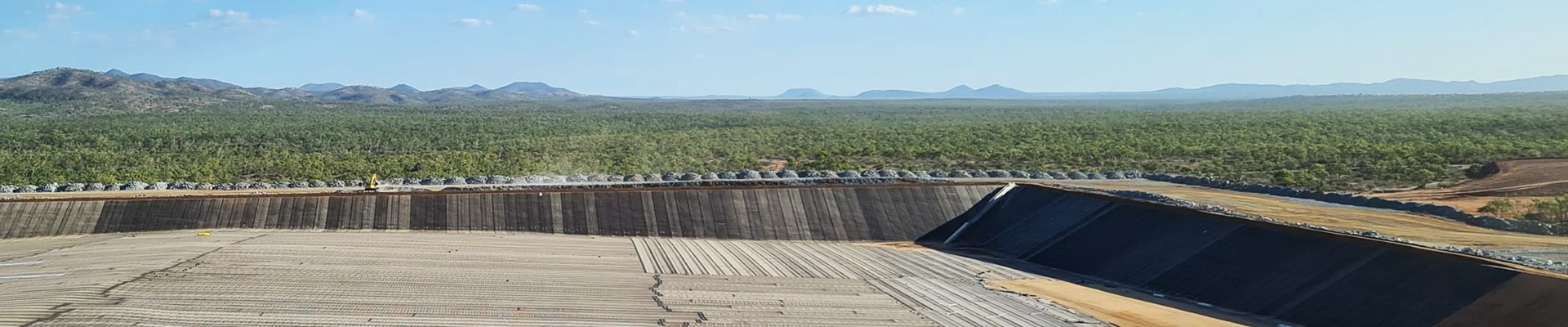

Reservoirs, Dams, and Canals: Used as the core impermeable layer to minimize water loss and enhance water resource utilization efficiency.

Artificial Lakes and Decorative Ponds: Ensures water body shape stability and long-lasting containment effectiveness in complex terrains.

Aquaculture: Fish Pond Liners and shrimp pond liners accelerate cleaning, improving breeding efficiency and hygiene standards.

3. Mining and Energy

Heap Leach Pads: Used in mining (e.g., gold extraction) to collect precious metal leachate, preventing chemical spills like cyanide.

Tailings Dams: Used for the disposal and containment of tailings, acting as a crucial barrier against environmental contamination.

Oil and Gas Fields: Utilized for the containment of drilling mud pits and produced water ponds.

Conclusion: Partnering for Premium HDPE Solutions

Whether your project demands the high friction of Textured HDPE for steep slopes or the high efficiency of Smooth HDPE for reservoir bottoms, selecting a supplier that adheres to international standards like ASTM and GRI-GM13 is essential.

We are dedicated to providing HDPE Geomembranes that meet the highest global standards, featuring reliable UV resistance and superior welding properties, ensuring your containment project achieves optimal long-term performance and environmental compliance.

Contact Us Now

Shandong Longxiang New Material Co., Ltd. specializes in providing a full range of high-quality HDPE lining solutions.

Contact us now for free samples and the latest quotes to meet your HDPE product specifications!

PROJECT CASES