Key to Enhancing Project Stability: A Comprehensive Analysis of Geotextiles and a Guide to Foreign Trade Procurement

Release time:

2025-11-10

As a professional geotextile exporter, we understand the challenges international buyers face when sourcing geotextiles. This guide provides an in-depth analysis of geotextile types, core functions, applications, and how to select high-quality products that meet your project needs.

Introduction: Why are geotextiles the cornerstone of modern engineering?

In today's civil, water, and environmental projects, finding long-term, efficient, and economical solutions is a primary goal for contractors and engineers worldwide. Geotextiles, as a key geosynthetic material, are a revolutionary product born out of this need. They not only significantly improve project quality and extend the lifespan of infrastructure but also effectively reduce maintenance costs.

As a professional geotextile exporter, we understand the challenges international buyers face when sourcing. This guide will provide an in-depth analysis of geotextile types, core functions, applications, and how to select high-quality products that meet your project needs.

🔎 What is Geotextile?

Geotextile is a permeable textile made of synthetic fibers (usually polypropylene/PP or polyester/PET). Based on different manufacturing processes, it is mainly divided into two categories:

Non-woven Geotextile

Process: Usually made through needle punching or thermal bonding processes, the fibers are arranged randomly.

Characteristics: Excellent permeability, filtration, and elasticity. Like felt, it allows water to pass through while blocking soil particles.

Main Applications: Filtration, drainage, isolation, and protection.

Woven Geotextile

Process: Woven using methods similar to traditional textiles, the fibers are arranged in a regular warp and weft direction.

Characteristics: Extremely high tensile strength and low elongation.

Main Applications: Reinforcement, stabilization of soft soil foundations, and stress dispersion.

🚧 Five Core Functions of Geotextile

Understanding the functions of geotextile is a prerequisite for its correct application. In various engineering scenarios, it primarily serves one or more of the following functions:

1. Separation

Function: Provides a barrier between two soil layers with different particle sizes (such as subgrade and base course), preventing them from mixing.

Advantages: Maintains the mechanical properties of the materials, preventing pavement settlement.

Applications: Highways, railways, parking lots, airport runways.

2. Filtration

Function: Allows water to pass freely while preventing the loss of fine soil particles.

Advantages: Prevents water erosion and pipe blockage, maintaining structural stability.

Applications: Retaining walls, drainage ditches, riverbank protection (geotextile bags).

3. Drainage

Function: Collects and guides excess water or gas within the geotextile plane.

Advantages: Reduces pore water pressure in the soil, preventing soil liquefaction.

Applications: Tunnels, landfills, sports fields, building foundations.

4. Reinforcement

Function: Utilizes the high tensile strength of geotextiles to enhance the bearing capacity and stability of the soil.

Advantages: Improves slope stability and repairs weak foundations.

Applications: Steep slopes, reinforced soil structures, embankments.

5. Protection

Function: Acts as a buffer layer to prevent other geosynthetic materials (such as geomembranes) from being punctured by sharp rocks.

Advantages: Ensures the integrity and durability of the seepage prevention system.

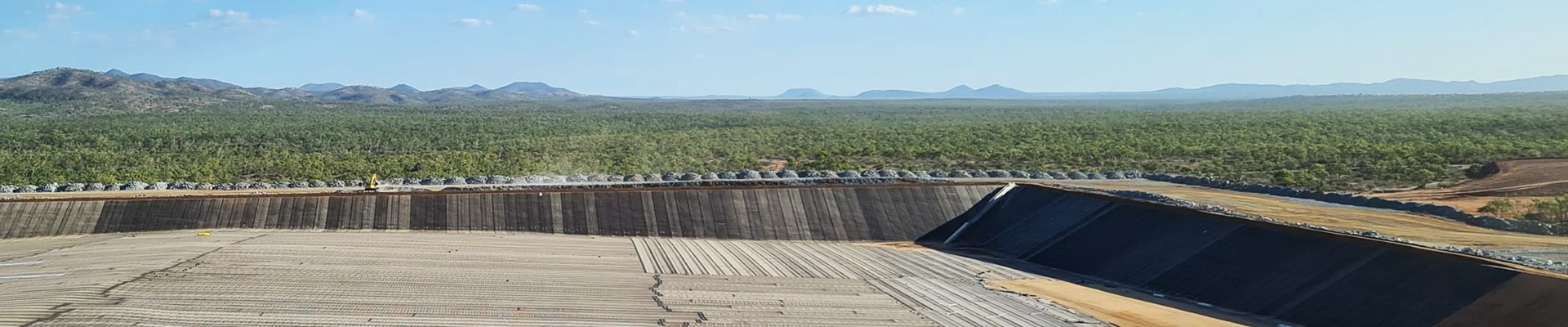

Applications: Landfills, artificial lakes, mining tailings dams.

📈 How to Choose the Right Geotextile Specifications for Your Project?

As an international buyer, when procuring geotextiles, you need to clarify the following key technical specifications with your supplier:

Material:

Do you need polypropylene (PP) or polyester (PET)? (PP has better acid and alkali resistance, while PET has higher strength and better creep resistance).

Type:

Non-woven or woven?

Weight / Mass per Unit Area:

This is the most common indicator, measured in g/m^2 (grams per square meter). Higher weight usually means higher thickness and strength.

For example: 150g/m², 200g/m², 300g/m², etc.

Strength:

Tensile strength: The core indicator for woven geotextiles.

CBR Puncture Strength: A key indicator of a nonwoven geotextile's resistance to puncture.

Hydraulic Properties:

Permittivity: The rate at which water passes through.

Equivalent Pore Size (AOS / O90): A crucial factor in filtration performance.

UV Resistance:

This is critical if the geotextile needs to be exposed to sunlight for extended periods.

🌍 Why Choose Us as Your Geotextile Supplier?

In the global geotextile market, choosing a reliable partner is crucial. We are committed to providing:

International Standard Certification: Our products strictly adhere to ASTM and ISO international standards, ensuring that every roll of geotextile meets your project requirements.

Full Product Range: Whether you need nonwoven geotextiles for drainage or high-strength woven geotextiles for reinforcement, we offer a one-stop solution.

Customized Services: We can customize production according to your specific geotextile specifications (weight, width, color, roll length).

Extensive Export Experience: We are familiar with international trade processes, logistics, and documentation requirements, ensuring your goods arrive safely and on time.

Highly Competitive Pricing: As a direct manufacturer, we can help you effectively control procurement costs while ensuring quality.

Act Now: Get Your Geotextile Solution

Whether your project is a large-scale infrastructure construction or an environmental remediation project, high-quality geotextiles are the guarantee of success.

Contact our team of experts now, submit your project requirements or geotextile specifications, and we will provide you with free technical consultation and the most competitive quote (Get a Quote)!

PROJECT CASES