HDPE pond liners: providing the ultimate leak-proof solution for your aquaculture, agricultural, and industrial projects.

Release time:

2025-11-14

Looking for durable and reliable HDPE pond liners? Our high-density polyethylene geomembranes offer superior UV resistance, chemical resistance, and high strength, making them ideal for aquaculture, irrigation, and industrial waterproofing. Contact us today for a quote.

Introduction: Protecting Your Precious Resources

In today's world, water resource management is crucial, whether for agricultural irrigation, aquaculture, or industrial wastewater treatment. A reliable seepage control system is key to ensuring project success, preventing pollution, and maximizing return on investment. Among numerous seepage control materials, HDPE (high-density polyethylene) pond liners (also commonly known as HDPE geomembranes) have become the preferred solution for professionals worldwide due to their superior performance.

What is HDPE pond liner?

HDPE pond liner is a thermoplastic impermeable material made of high-density polyethylene resin. It is produced through a precision blow molding or flat extrusion process and is specifically designed to resist the erosion of harsh natural environments and chemicals. Its robust molecular structure makes it highly impermeable, making it an ideal barrier for water and waste containment.

Why Choose HDPE Pond Liners?

For project managers and purchasers seeking long-term, maintenance-free solutions, HDPE liners offer an unparalleled combination of advantages:

Superior Durability and High Strength: HDPE boasts excellent puncture resistance, tear resistance, and high tensile strength. It can withstand the stresses of installation and long-term environmental pressures, with a service life of decades.

Excellent Chemical Resistance: HDPE effectively resists fertilizers and pesticides used in agriculture, as well as acids, alkalis, and toxic solvents in industrial wastewater, ensuring that chemicals do not leak into the surrounding environment.

Superior UV Resistance: Many liners degrade rapidly under direct sunlight. Our HDPE pond liners incorporate high-quality carbon black and UV stabilizers during the manufacturing process, maintaining their integrity and performance even under the strongest sunlight conditions.

High Cost-Effectiveness: While the initial investment may be higher than some alternative materials, HDPE's extremely long service life and minimal maintenance requirements make it the most cost-effective choice. It reduces losses due to leaks and costly repairs.

Safe and environmentally friendly (aquaculture friendly): Our HDPE liners are made from 100% virgin resin and contain no harmful additives or plasticizers. They are completely safe for aquatic life (such as fish and shrimp), will not pollute the water, and are ideal for aquaculture projects.

Key Application Areas of HDPE Geomembranes

The versatility of HDPE geomembranes makes them suitable for projects of all sizes worldwide:

Aquaculture:

Leakage prevention for fishponds and shrimp ponds.

Water quality control and prevention of disease transmission.

Improving feed conversion rates and simplifying the harvesting process.

Agriculture & Irrigation:

Leakage prevention for irrigation canals, reservoirs, and water storage ponds.

Ensuring that precious water resources are not lost due to leakage.

Liners for manure silos (biogas digesters) and composting sites.

Industrial & Environmental:

Wastewater treatment ponds and evaporation ponds.

Secondary leakage prevention in hazardous materials and chemical storage areas.

Heap leaching ponds and tailings dams in mining.

Civil Engineering:

Landscape lakes and golf course water features.

Sealing and lining of landfills.

Choosing the Right HDPE Pond Liner Supplier (Buyer's Guide)

As a global buyer, you should consider the following key factors when sourcing HDPE liners:

Product Specifications (Thickness): The thickness of the liner (usually expressed in millimeters, mm, or mils) is crucial. Lighter applications, such as small landscape ponds, may use 0.5mm, while heavy industrial or large reservoir applications require 1.5mm to 2.0mm or thicker material.

Quality Standards and Certifications: Ensure the supplier's products meet or exceed international standards, such as GRI-GM13 (the industry gold standard for geomembranes). Inquire about ISO certifications and other relevant quality control documentation.

Material Quality (Raw Material): Insist on using 100% virgin polyethylene resin, not recycled materials. Recycled materials may reduce the liner's strength, durability, and chemical resistance.

Technical Support and Installation: Reliable suppliers provide not only products but also technical support. While HDPE liners are very durable, their performance largely depends on professional welding and installation.

Why Choose Us as Your HDPE Pond Liner Partner?

As a leading HDPE geomembrane manufacturer and global supplier, we are committed to providing the highest standards of products and services for your projects.

Our Commitment:

Strict Quality Control: All our HDPE pond liners are manufactured on state-of-the-art production lines and strictly adhere to GRI-GM13 and ISO 9001 standards.

100% Virgin Resin: We use only premium virgin HDPE resin from top suppliers, ensuring the long-term performance of our products.

Customized Solutions: We can provide liners of different thicknesses, widths, and surface textures (smooth or textured) to meet your specific project needs.

Global Logistics Experience: We have extensive experience in international trade and logistics, ensuring your goods arrive safely and on time at any port worldwide.

Contact us today for your project solutions.

Don't let leaks jeopardize your project's success. Choosing high-quality HDPE pond liners is your wisest long-term investment.

Whether you're working on a large aquaculture farm, an agricultural irrigation system, or a complex industrial waterproofing project, our team of experts is ready to assist you.

Contact us today to discuss your project specifications, obtain free product samples, or receive a competitive quote.

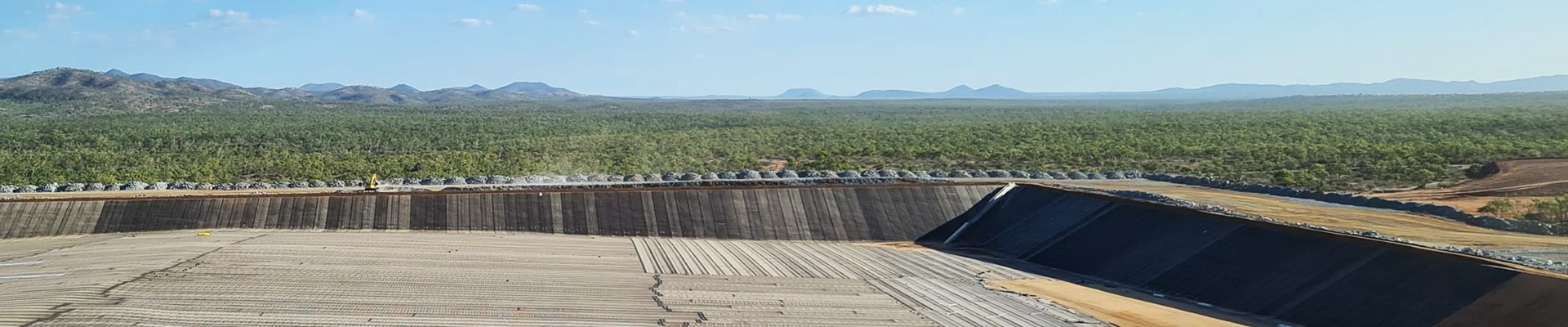

PROJECT CASES