High-performance bentonite waterproofing blankets (GCLs) – Your reliable seepage barrier for civil engineering projects

Release time:

2025-11-18

High-performance bentonite waterproofing blankets (GCLs), as an environmentally friendly, efficient, and self-healing waterproofing material, are widely used in landfills and water conservancy projects. Shandong Longxiang New Materials provides high-quality products that meet international standards and professional export services.

I. Introduction

In today's civil engineering field, where environmental protection and infrastructure quality requirements are increasingly stringent, bentonite geotextile blankets (GCLs) are rapidly becoming an ideal alternative to traditional compacted clay liners (CCLs). As an innovative geosynthetic material, GCLs have won the favor of engineering contractors and designers worldwide due to their superior impermeability, easy installation process, and excellent cost-effectiveness. This article will delve into the technical advantages and main application scenarios of GCLs, and explain why they can become a reliable waterproofing barrier for your next major engineering project.

II. What is a Bentonite Waterproof Blanket (GCL)?

A bentonite waterproof blanket, or GCL for short, is a composite waterproofing material. It consists of a layer of natural sodium-based bentonite granules, fixed between two layers of geotextile or geomembrane using needle-punching or adhesive techniques.

Core Component: Sodium-based bentonite

When bentonite comes into contact with water, it hydrates and swells, forming a dense, low-permeability gel.

This self-sealing gel layer is key to the ultra-low permeability of GCL.

III. GCL's technical advantages: Why choose bentonite waterproof blankets?

Choosing GCL means choosing reliability, efficiency, and cost control.

Key Features | Technical Specification | Buyer Benefit |

|---|---|---|

Excellent low permeability | The permeability coefficient is typically less than $5 \times 10^{-11} \text{ m/s}$ | It provides the most reliable seepage prevention effect and effectively protects groundwater resources. |

Self-healing ability | Bentonite can automatically seal small punctures and cracks after it swells when it comes into contact with water. | Long-term durability reduces the risk of damage during installation or use. |

Installation is simple and quick. | Lightweight and highly flexible, it can be laid over large areas without the need for heavy machinery to compact it. | It significantly shortens the construction period and saves on labor and machinery rental costs. |

Environmentally friendly materials | It is made from natural clay minerals and is a green and environmentally friendly waterproof material. | It complies with increasingly stringent international environmental standards, which facilitates project approval. |

Save space | A thickness of only a few millimeters can achieve the same seepage prevention effect as a compacted clay lining that is several meters thick. | Maximize the effective volume of landfills or reservoirs. |

IV. Main Application Scenarios of Bentonite Waterproofing Blankets

GCLs, due to their versatility, are widely used in various civil and environmental engineering projects worldwide.

Landfills: As a key impermeable layer in bottom lining and closure systems, effectively preventing contaminant leakage.

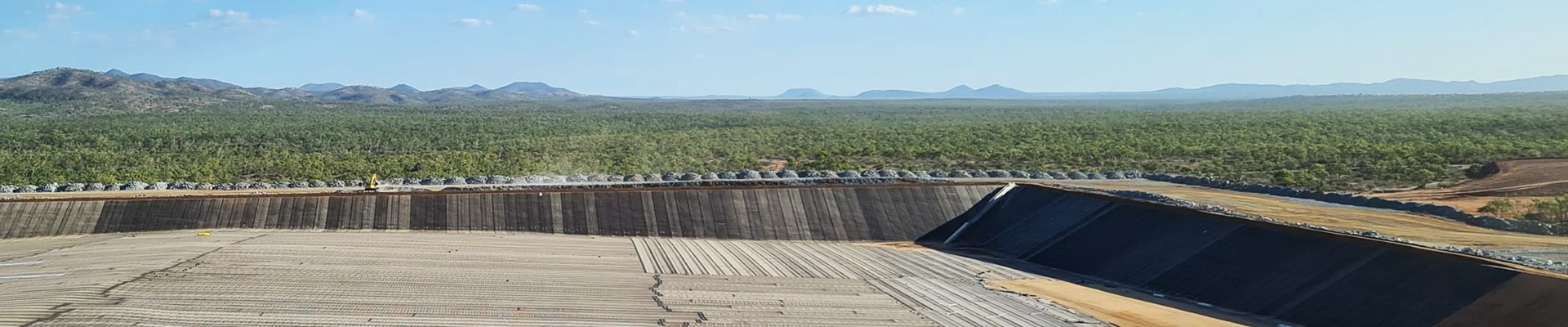

Hydraulic Structures: Used for seepage prevention in reservoirs, artificial lakes, ponds, and irrigation canals, minimizing water loss.

Mining and Tailings Treatment: Isolates toxic substances and acid mine drainage (AMD) from mining operations.

Below Grade Structures: Waterproofing the exterior of building basements, tunnels, and underground passages.

V. Call to Action

Contact us today for free samples and the latest GCL product specifications!

If you are looking for an efficient and reliable waterproofing barrier for your water, environmental, or civil engineering projects, please fill out the inquiry form below or send an email directly. Our professional team will provide you with customized solutions and the most competitive factory prices within 24 hours.

PROJECT CASES