Standard Certified By

Fiberglass Geogrid

Classification :

PRODUCT DETAILS

What is a Fiberglass Geogrid?

Fiberglass Geogrid is a main geosynthetic material, compared with other geosynthetics, it has unique performance and efficacy. It is often used as reinforcement for reinforced soil structures or reinforcement for composite materials.

Fiberglass Geogrids are divided into four categories: plastic Fiberglass Geogrids, steel-plastic Fiberglass Geogrids, glass fiber Fiberglass Geogrids and polyester warp-knitted polyester Fiberglass Geogrids. The grid is a two-dimensional grid or a three-dimensional grid screen with a certain height made of polypropylene, polyvinyl chloride and other polymers through thermoplastic or molded. When used as a civil engineering, it is called geotechnical grille.

Specification:

Width:1m-6m or follow customers' demand

Length:50-100m or follow customers' request

Tensile strength: 22Kn/m--1000Kn/m

Mesh Size:12.7*12.7mm. 25.4*25.4mm

Color: Black

What are the applications of Fiberglass Geogrid?

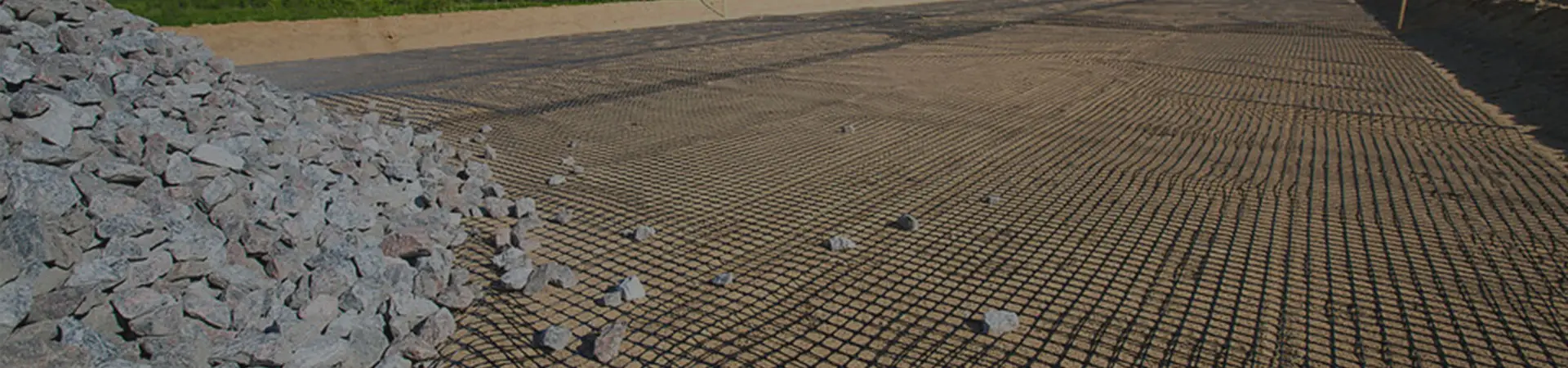

It is suitable for roadbed reinforcement and road surface reinforcement of various roads, railways, and airports.

It is suitable for foundation reinforcement of permanent bearings such as large parking lots and wharf yards.

It is suitable for slope protection of railways and highways.

Applicable culvert enhancements.

It is suitable for the secondary reinforcement of the soil slope reinforced by unidirectional tensile Fiberglass Geogrid, further strengthening the soil slope and preventing soil erosion.

Mine and tunnel reinforcement.

Fiberglass Geogrid is suitable for reinforcement of various embankments and subgrades, slope protection, and reinforcement of cave walls. Reinforcement of permanent load-carrying foundations in large airports, parking lots, wharf yards, etc.

Fiberglass Geogrid is used to increase the bearing capacity of road (ground) foundation and prolong the service life of road (ground) foundation.

Fiberglass Geogrid is used to prevent the road (ground) surface from subsidence or cracks, and keep the ground beautiful and tidy.

Fiberglass Geogrid is used for convenient construction, saving time and effort, shortening the construction period and reducing maintenance costs.

Fiberglass Geogrids are used to prevent cracks in culverts.

Fiberglass Geogrids are used to strengthen soil slopes and prevent soil erosion.

Fiberglass Geogrid is used to reduce the thickness of the cushion and save the cost.

The Fiberglass Geogrid is used to support the stable green environment of the grass planting mat on the slope.

Fiberglass Geogrid can effectively block the transmission of seismic force, and plays an important role in enhancing the seismic stiffness, strength and stability of embankments.

The successful application of Fiberglass Geogrid is expected to reduce various common embankment diseases in high-intensity earthquake areas and improve the earthquake resistance and disaster reduction ability of roads. However, the current codes for seismic design of highways and railways do not make corresponding regulations on the seismic performance of Fiberglass Geogrid-reinforced embankments.

Product Performance of Fiberglass Geogrid

It has high strength, low creep, and adapts to various environmental soils, which can fully meet the use of tall retaining walls in high-grade highways.

It can effectively improve the interlocking and occlusion of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.

Compared with the traditional grille, it has the characteristics of high strength, strong bearing capacity, corrosion resistance, anti-aging, large friction coefficient, uniform holes, convenient construction and long service life.

It is more suitable for deep-sea operations and embankment reinforcement, and fundamentally solves the technical problems of low strength, poor corrosion resistance, and short service life caused by long-term seawater erosion of gabions made of other materials.

It can effectively avoid the construction damage caused by being crushed and damaged by machines and tools during the construction process.

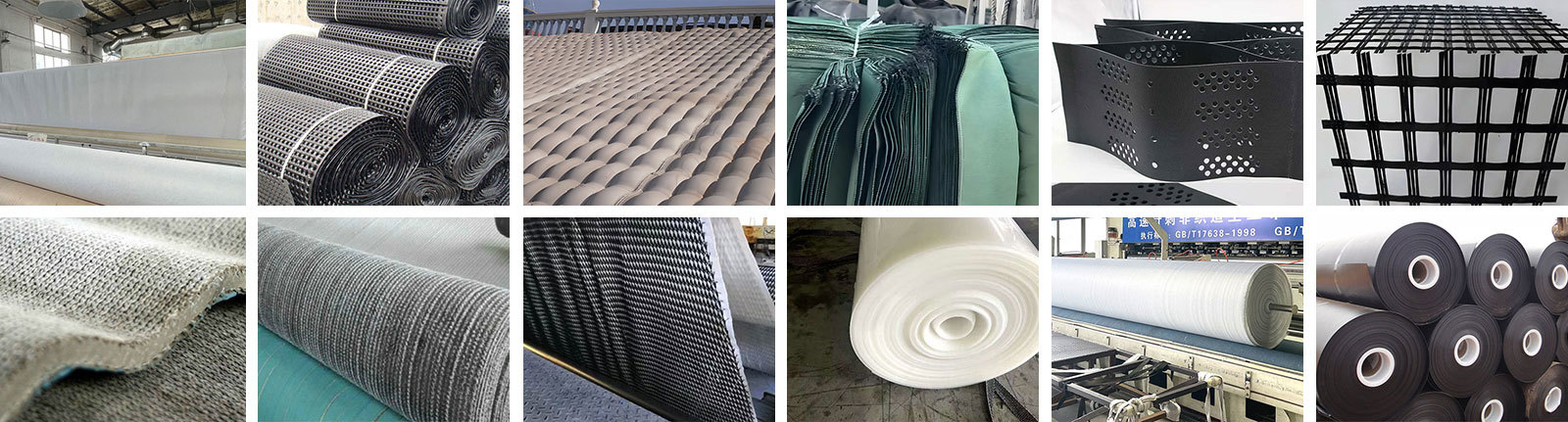

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE