Standard Certified By

Sodium Bentonite Geosynthetic Clay Liners | Reinforced GCL Barriers

Classification :

PRODUCT DETAILS

1. Product Overview

Longxiang New Materials offers premium Sodium Bentonite Geosynthetic Clay Liners (GCLs), designed as the ultimate hydraulic barrier for demanding environmental projects. Our Reinforced GCL Barriers are engineered using a specialized needle-punching process that mechanically bonds high-swelling natural sodium bentonite clay between two durable geotextile layers.

Unlike standard clay liners, our reinforced structure provides exceptional internal shear strength, making it the ideal solution for steep slopes, landfill caps, and vertical applications where stability is critical.

2. Why Choose Reinforced Sodium Bentonite GCL?

High-Quality Sodium Bentonite Core: We use only natural sodium bentonite with a high montmorillonite content. This material swells up to 15-20 times its dry volume when hydrated, creating a dense, impermeable gel that effectively seals against liquid migration.

Needle-Punched Reinforcement: Thousands of high-strength fibers are punched through the bentonite core, locking the top and bottom geotextiles together. This "reinforced" structure prevents the clay from shifting or slumping, ensuring long-term integrity even on steep gradients.

Self-Sealing Technology: The active sodium bentonite automatically seals minor punctures caused by installation damage or uneven subgrades, providing a "healing" effect that synthetic membranes cannot offer.

Superior Shear Resistance: Designed to withstand high shear forces, ensuring the liner stays in place under heavy cover soil or waste loads.

3. Primary Applications

Our Reinforced GCL Barriers are specifically tailored for projects requiring high friction angles and slope stability:

Steep Landfill Side Slopes: Prevents liner slippage in waste containment cells.

Landfill Cappings (Closures): Provides a stable, impermeable barrier for final cover systems.

Tailings Dams & Mining: Effective containment for chemically aggressive mining leachates.

Canal & Dam Linings: Replaces traditional concrete or compacted clay in water infrastructure.

Secondary Containment: Fuel farms and tank storage areas where robust ground protection is required.

4. Technical Performance

| Property | Test Standard | Typical Value |

|---|---|---|

| Bentonite Type | - | Natural Sodium Bentonite |

| Swell Index | ASTM D5890 | ≥ 24 ml/2g |

| Fluid Loss | ASTM D5891 | < 18 ml |

| Peel Strength (Reinforcement) | ASTM D6496 | ≥ 60 N/10cm (High Bond) |

| Internal Shear Strength | ASTM D6243 | > 24 kPa (Typical) |

| Hydraulic Conductivity | ASTM D5887 | $\le 5 \times 10^{-11}$ m/s |

Note: We can adjust the geotextile mass and bentonite load to meet specific project specifications (e.g., GRI-GCL3 standards).

5. Installation & Handling

Installing Sodium Bentonite Geosynthetic Clay Liners is faster and more cost-effective than traditional compacted clay liners (CCL).

Less Excavation: Replaces meters of clay with a few millimeters of GCL, maximizing landfill airspace.

All-Weather Installation: Can be installed in various weather conditions (unlike CCL which is sensitive to moisture).

Simple Deployment: Rolls can be deployed using standard spreader bars and construction equipment.

Overlap Guide: Our GCLs feature marked overlap lines to ensure proper seaming and continuous sealing.

6. FAQ: Reinforced GCLs

- Q: Why is "Sodium" Bentonite better than Calcium Bentonite?

A: Sodium bentonite has a much higher swelling capacity (15x+) compared to calcium bentonite. This high swell is essential for creating a watertight seal and for the "self-healing" properties of the liner.

- Q: What does "Needle-Punched Reinforced" mean?

A: It refers to the manufacturing process where barbed needles pull fibers from the upper non-woven geotextile through the bentonite clay and into the lower carrier geotextile. This mechanical bonding increases the Peel Strength, preventing the liner from delaminating.

- Q: Can this GCL be used on steep slopes?

A: Yes. Because it is reinforced, our GCL has high internal shear strength, making it suitable for slopes as steep as 3:1 or even 2:1, depending on the specific design friction analysis.

7. Get a Quote

Looking for High-Stability GCL Solutions?

Contact Longxiang New Materials today for technical data sheets, free samples of our Reinforced Sodium Bentonite GCL, and competitive wholesale pricing.

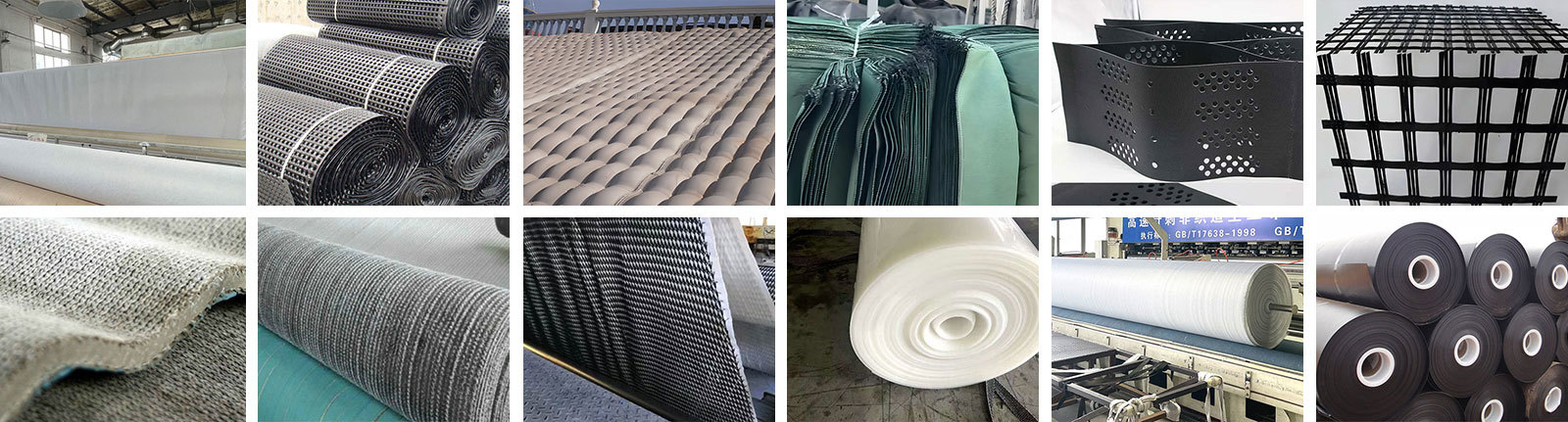

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE