Why EVA Geomembrane is the Superior Choice for Complex Lining Projects

Release time:

2026-01-29

Discover why EVA geomembrane is the top choice for complex engineering. Learn about its superior flexibility, stress-crack resistance, and why it outperforms HDPE in tunnels and roofing.

In the world of containment and waterproofing, not all membranes are created equal. While HDPE is a household name, EVA (Ethylene Vinyl Acetate) Geomembrane is the "secret weapon" for engineers dealing with irregular terrains and high-stress environments.

What Makes EVA Different?

Unlike traditional polyethylene liners, EVA is a copolymer that balances the strength of plastics with the elasticity of rubber. This unique molecular structure provides several key advantages:

Exceptional Flexibility: EVA can easily conform to uneven surfaces, making it the go-to material for tunnel linings and complex architectural foundations.

Superior Stress-Crack Resistance: It handles thermal expansion and contraction far better than rigid materials, drastically reducing the risk of leaks over time.

Low-Temperature Performance: Even in sub-zero conditions, EVA maintains its integrity without becoming brittle.

Primary Applications

Tunnel Construction: Its ability to withstand high hydraulic pressure while remaining flexible makes it essential for railway and highway tunnels.

Roofing & Basements: For high-end commercial buildings, EVA provides a long-lasting moisture barrier that adapts to the building's natural settling.

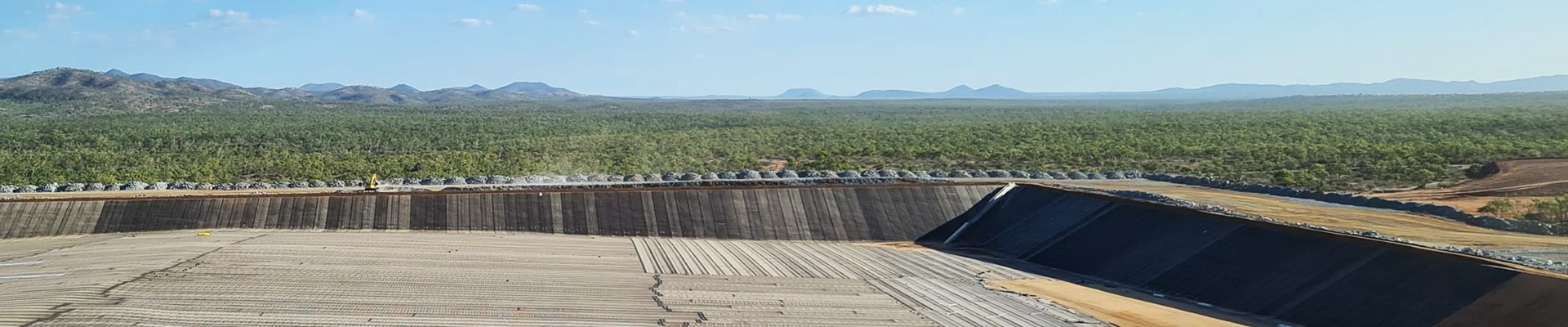

Aquaculture: Its non-toxic properties and puncture resistance make it ideal for high-value fish farming ponds.

Conclusion

If your project involves sharp angles, extreme temperatures, or requires long-term durability under stress, EVA geomembrane is an investment that prevents costly repairs down the line.

PROJECT CASES