How Non-woven Geotextile Fabric Enhances the Efficiency of Drainage Systems

Release time:

2026-01-16

Discover how non-woven geotextile fabric improves the longevity of drainage systems. Learn about its critical roles in filtration, separation, and soil stabilization in civil engineering.

In civil engineering and landscaping, the primary enemy of structural integrity is often hidden underground: uncontrolled water flow. Non-woven geotextile fabric has emerged as a critical component in managing this challenge, offering a versatile solution for drainage and filtration.

The Filtration Powerhouse

Unlike woven materials, non-woven geotextiles are manufactured by bonding fibers together through needle-punching or thermal methods. This creates a complex, three-dimensional pore structure that allows water to pass through freely while retaining fine soil particles. This prevents the "clogging" of drainage pipes and ensures the system remains functional for decades.

Separation: Preventing Subgrade Contamination

One of the most common causes of road or pavement failure is the mixing of the subgrade soil with the expensive aggregate base. A layer of high-quality geotextile acts as a durable barrier, maintaining the integrity of the different soil layers and increasing the load-bearing capacity of the entire structure.

Key Applications

French Drains: Wrapping perforated pipes to prevent silt buildup.

Retaining Walls: Reducing hydrostatic pressure behind the wall.

Road Construction: Extending the lifespan of highways by preventing base contamination.

Conclusion

Investing in the right grade of non-woven geotextile is not just a construction choice; it is a long-term insurance policy for your infrastructure. By ensuring proper filtration and separation, you significantly reduce future maintenance costs.

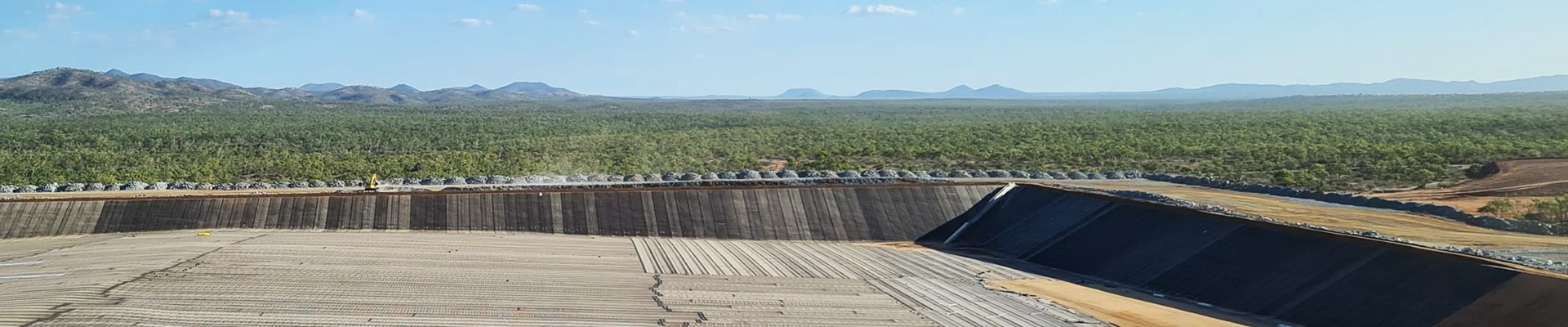

PROJECT CASES