Securing the Future of Mining: The Critical Role of HDPE Geomembrane Liners

Release time:

2026-01-16

Protect the environment and your mining operation with high-performance HDPE geomembrane liners. Explore their chemical resistance and durability in tailing pond applications.

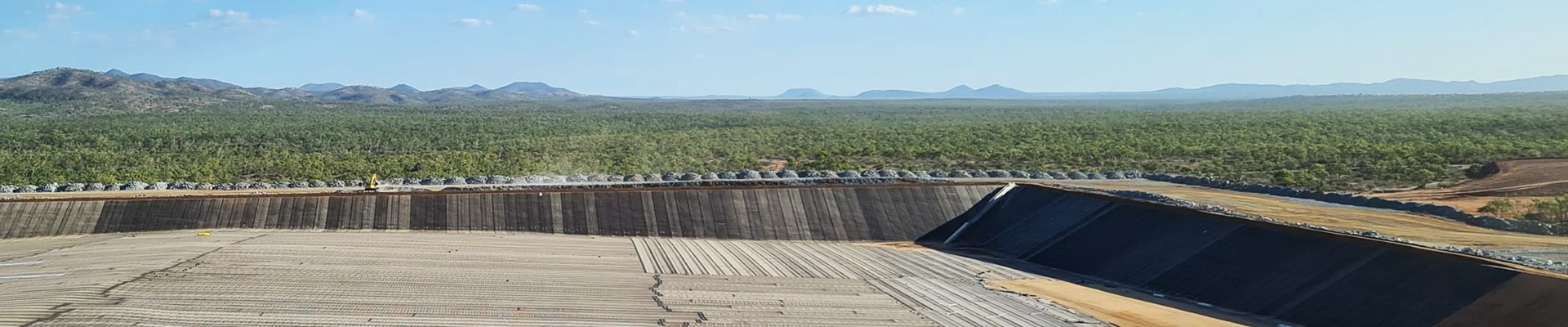

Mining operations face immense pressure to balance production efficiency with environmental responsibility. Tailing ponds, which store the byproducts of mineral processing, represent a significant environmental risk if not properly contained. HDPE (High-Density Polyethylene) geomembrane liners have become the global standard for securing these critical areas.

Why HDPE for Mining?

The harsh environment of a mine requires materials that can withstand more than just water pressure. HDPE geomembranes are selected for their:

Superior Chemical Resistance: They remain stable even when exposed to acidic or alkaline leachates common in mining waste.

High Puncture Resistance: Essential for handling the rough terrain and heavy debris typical of tailing impoundments.

UV Stability: Designed to withstand long-term exposure to direct sunlight in open-pit mining sites.

Preventing Groundwater Contamination

The primary function of an HDPE liner in a tailing pond is to create an impermeable barrier. By preventing toxic chemicals from seeping into the groundwater, mining companies not only comply with strict environmental regulations but also protect the surrounding ecosystem and community health.

Installation Excellence

A liner is only as good as its seams. For large-scale mining projects, using high-quality welding technology and rigorous leak detection ensures that the containment system is 100% effective. Choosing a supplier that provides both high-grade material and technical support is vital for project success.

Summary

As the mining industry moves toward more sustainable practices, the importance of robust containment systems cannot be overstated. HDPE geomembranes offer a reliable, durable, and cost-effective way to manage waste and protect the planet.

PROJECT CASES