Securing the Future: High-Performance Geomembranes for Modern Landfill Containment

Release time:

2026-01-29

Ensure environmental safety with high-performance landfill geomembranes. Learn about leachate collection, chemical resistance, and the role of HDPE in waste management.

Landfill management is no longer just about digging a hole; it’s about sophisticated environmental engineering. The heart of this system is the Landfill Geomembrane, the primary barrier preventing hazardous leachate from contaminating groundwater.

The Critical Role of HDPE in Waste Management

Most modern landfills utilize HDPE (High-Density Polyethylene) geomembranes due to their incredible chemical inertness. When dealing with the unpredictable "chemical soup" of landfill leachate, you need a liner that won't degrade.

Chemical Resistance: HDPE stands up to acids, alkalis, and organic solvents found in municipal and industrial waste.

Puncture Toughness: Withstanding the weight of thousands of tons of waste requires high tensile strength and puncture resistance.

UV Stability: During the installation phase, these liners are often exposed to direct sunlight. Our geomembranes are treated with high-quality carbon black to prevent UV degradation.

System Components: Beyond Just a Liner

A robust landfill containment system typically involves:

Primary Liner: Usually a 1.5mm to 2.5mm HDPE geomembrane.

Secondary Containment: Often incorporating GCL (Geosynthetic Clay Liners) for double security.

Capping System: Once a landfill reaches capacity, an EVA or LLDPE geomembrane is used for "capping" to prevent rainwater from entering the waste mass.

Meeting Global Standards

For international projects, ensuring your materials meet GRI-GM13 standards is non-negotiable. Using premium-grade resins ensures that your landfill project meets environmental regulations for decades, not just years.

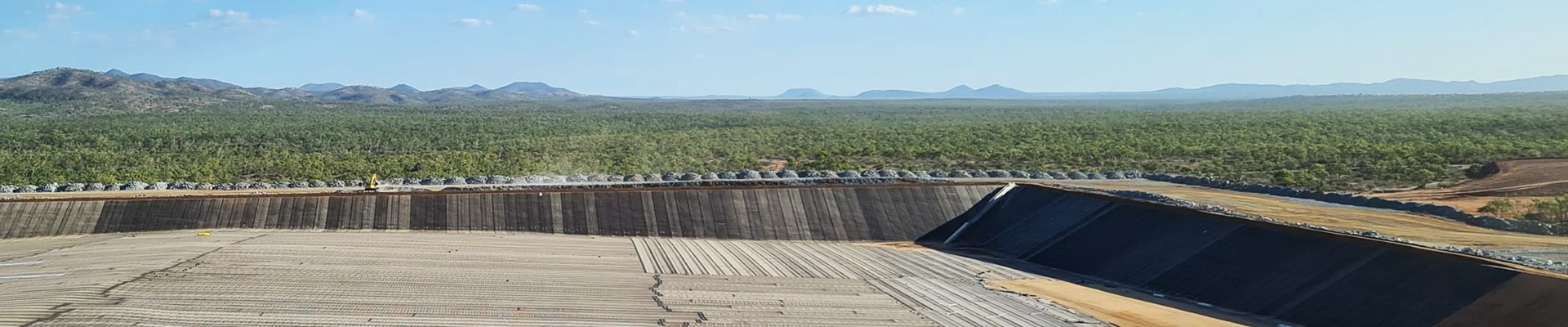

PROJECT CASES