Standard Certified By

High Density Polyethylene (HDPE) Geomembrane Liner

Classification :

PRODUCT DETAILS

1. High Density Polyethylene (HDPE) Geomembrane Liner

Our HDPE Geomembrane Liner is the most widely used geosynthetic product in the world for containment applications. Manufactured from premium virgin polyethylene resins, this impermeable sheet provides a robust and reliable barrier against seepage and environmental contamination. Known for its exceptional durability, chemical inertness, and long service life, HDPE Geomembrane is the foundational element for critical infrastructure, environmental protection, and valuable resource containment. We produce liners ranging from 0.3mm to 3.0mm to meet stringent global standards, including ASTM GRI-GM13.

2. Core Advantages of HDPE Geomembrane

-

Unrivaled Chemical Resistance: HDPE is inherently inert, making it highly resistant to a vast range of chemicals, acids, alcohols, and waste leachate found in industrial and municipal environments.

-

Superior Anti-Seepage: The low permeability coefficient of HDPE creates a near-perfect watertight barrier, crucial for preserving water resources and protecting groundwater.

-

Excellent UV Stability: Formulated with 2.0% to 3.0% Carbon Black, our liners offer outstanding resistance to UV degradation, making them suitable for prolonged exposed applications.

-

High Durability & Longevity: Offers exceptional tensile strength, tear resistance, and puncture resistance, ensuring a design life that can exceed 50 years when buried.

-

Cost-Effective Solution: HDPE is the most economical geomembrane material per square meter for large-scale engineering projects.

3. Surface Options and Specifications

To accommodate diverse engineering requirements, our HDPE Geomembranes are available in three primary surface finishes, each serving a specific structural purpose:

3.1 Smooth HDPE Geomembrane

-

Application: Ideal for flat basal areas, bottom liners, and low-friction applications where maximum intimate contact and high liquid flow rates are required.

-

Key Feature: Easier to clean and suitable for pre-fabrication welding.

3.2 Textured HDPE Geomembrane

-

Application: Essential for steep slopes in landfills, reservoirs, and mining heap leach pads.

-

Key Feature: The rough surface dramatically increases the interface friction angle, preventing slippage of overlying soil, protective layers, or waste mass. Available in single-sided and double-sided textures.

4. Key Application Markets

| Market Segment | Primary Applications | Recommended Thickness |

| Environmental Protection | Landfill Bottom Liner, Landfill Capping, Hazardous Waste Containment, Secondary Containment | 1.5mm, 2.0mm, 2.5mm |

| Mining | Heap Leach Pads (Gold/Copper), Tailings Dams, Process Solution Ponds, Acid Mine Drainage (AMD) Control | 2.0mm, 1.5mm |

| Water Conservancy | Large Water Reservoirs, Irrigation Canals, Dams, Stormwater Retention Ponds | 1.0mm, 1.5mm |

| Aquaculture & Agriculture | Fish Ponds, Shrimp Farming, Farm Water Storage, Water Treatment Lagoons | 0.5mm, 0.75mm |

| Specialty Containment | Biogas Digester Covers, Root Barriers, Subway Waterproofing, Wastewater Treatment | 1.5mm, 0.5mm |

5. Compliance, Quality, and Manufacturing

We are committed to delivering material that meets the highest standards for critical civil engineering projects.

-

ASTM GRI-GM13 Standard: All our geomembranes are produced and tested according to the rigorous GRI-GM13 specification, the internationally recognized benchmark for HDPE liner quality.

-

Advanced Equipment: We utilize state-of-the-art automated production lines to ensure uniform thickness, density, and consistency across every roll.

-

Quality Assurance: Every batch is subjected to destructive and non-destructive testing, including full compliance with GRI-GM13 requirements for Density, Tensile Strength, and Environmental Stress Crack Resistance (ESCR).

6. Explore By Thickness

To find the perfect liner for your specific project requirements, click on the relevant thickness below:

-

[0.5mm HDPE Liner] – Ideal for Aquaculture Pond Liners and Root Barriers.

-

[1.0mm HDPE Liner] – Standard for Agriculture Water Reservoirs and Canal Lining.

-

[1.5mm HDPE Liner] – The global standard for Municipal Landfill Bottom Liners and Biogas Covers.

-

[2.0mm HDPE Liner] – Heavy-Duty requirement for Mining Heap Leach Pads and industrial waste.

-

[2.5mm HDPE Liner] – Maximum safety factor for Hazardous Waste Secondary Containment.

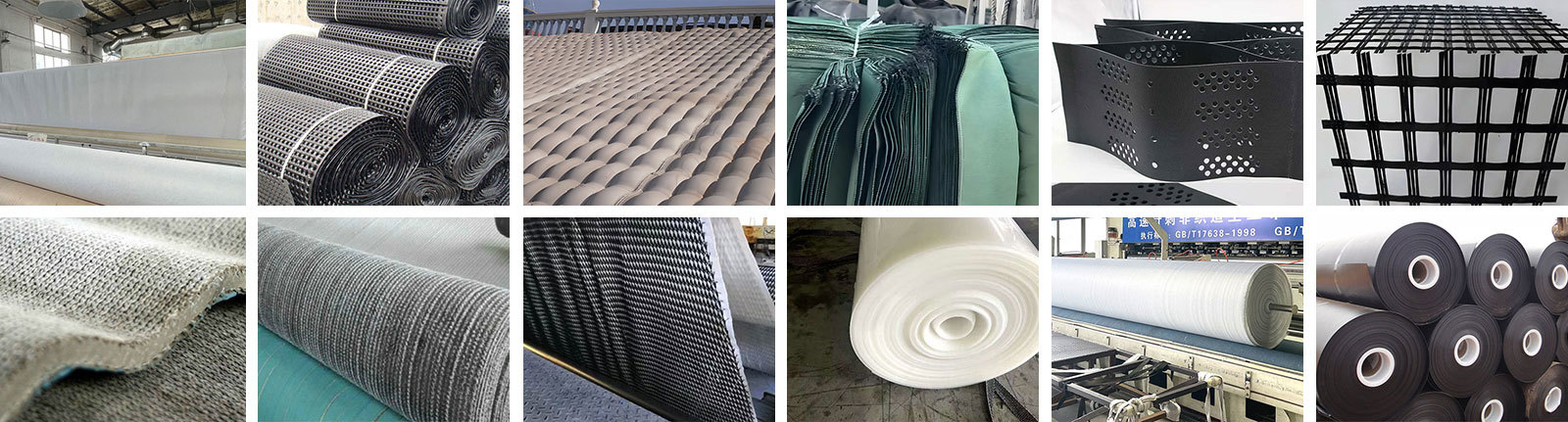

Main Products

PROJECT CASES

APPLICATION AREAS

Geotechnical material series are widely used in various fields such as highways, railways, tunnels, water conservancy of reservoirs and canals, artificial lakes, environmental protection, sewage treatment, landfills, anti-seepage of tailings reservoir areas, and livestock breeding.

Water conservancy projects

Geosynthetics play a vital role in water conservancy projects such as dams and reservoirs, canals and channels, and riverbank protection.

Breeding industry

In the aquaculture industry, geosynthetics such as geomembranes and geotextiles can be used to create healthy aquaculture ponds, ensure stable water quality and reduce water resource consumption. All geosynthetics provided by can be customized according to customer needs.

Road construction

The geosynthetics such as geomembranes, geotextiles, geogrids, geocells, etc. provided by play an irreplaceable role from roadbed treatment to pavement protection, from drainage systems to environmental protection isolation.

Agricultural

In agricultural irrigation and biogas digester scenarios, geosynthetics such as geomembranes and geotextiles play a key role due to their respective characteristics. The products provided by Factory meet the standards and can be customized according to requirements.

Coastal Engineering

In coastal engineering, geosynthetics such as geobags, cement blankets, and geogrids play an important role in coastal engineering from coastal protection, structural reinforcement to slope stability, and effectively respond to the challenges brought by the complex geology and environment of coastal areas.

Environmental Protection

Factory provides customers with high-standard geosynthetics to meet their needs for building landfills.

LISTEN & DELIVER TRUSTED SOIUTIONS.

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

GET A FREE QUOTE